For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

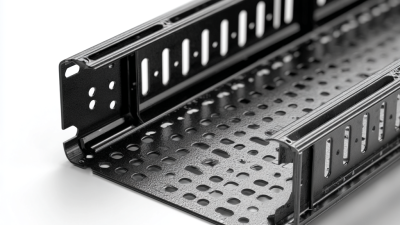

How to Choose the Right Metal Cable Tray for Your Electrical Installation

Choosing the right metal cable tray for your electrical installation is crucial for ensuring safety, durability, and efficiency in any project. According to a recent report by MarketsandMarkets, the metal cable tray market is projected to reach $6.76 billion by 2026, growing at a CAGR of 5.1% from 2021. This significant growth underscores the increasing reliance on metal cable trays in various sectors, including construction, manufacturing, and telecommunications, making it essential for professionals to make informed decisions about their selection.

Choosing the right metal cable tray for your electrical installation is crucial for ensuring safety, durability, and efficiency in any project. According to a recent report by MarketsandMarkets, the metal cable tray market is projected to reach $6.76 billion by 2026, growing at a CAGR of 5.1% from 2021. This significant growth underscores the increasing reliance on metal cable trays in various sectors, including construction, manufacturing, and telecommunications, making it essential for professionals to make informed decisions about their selection.

Industry expert John Smith, a leading figure in electrical installation consultancy, emphasizes the importance of choosing the right cable management system: "The efficiency and reliability of electrical installations can directly hinge on the quality and compatibility of the installed metal cable tray." His insight highlights that understanding the types, materials, and installation practices associated with metal cable trays is not merely a technical consideration but a foundational element that affects overall project success.

As the demand for structured cable management continues to rise, it becomes imperative for electrical engineers and project managers to evaluate their options carefully. Factors such as load capacity, environmental conditions, and compliance with industry standards will not only influence the performance of the metal cable trays but also ensure that installations comply with safety regulations. Learning how to navigate these considerations is key to optimizing both performance and safety in electrical installations.

Understanding the Different Types of Metal Cable Trays Available

When selecting the right metal cable tray for electrical installations, it's important to understand the different types available, as they play a crucial role in supporting and protecting electrical wiring. The U.S. cable tray market is categorized mainly into three materials: steel, aluminum, and stainless steel, each offering distinct advantages. Steel trays are known for their strength and durability, making them ideal for heavy-duty applications. Aluminum trays, on the other hand, are lightweight and resistant to corrosion, which can be advantageous in environments exposed to moisture. Stainless steel combines the benefits of both, offering strength along with excellent resistance to corrosion, making it suitable for specialized settings.

The types of metal cable trays include ladder, solid bottom, trough, and channel configurations. Ladder trays are particularly popular due to their versatility and efficient airflow, reducing overheating risks. According to recent industry analysis, the cable tray market is projected to reach approximately USD 5.4 billion, growing at a CAGR of 2.4% from 2025 to 2035. This growth underscores the increasing demand for reliable cable management solutions in various electrical applications, highlighting the importance of choosing the right type to ensure both safety and efficiency in installations.

How to Choose the Right Metal Cable Tray for Your Electrical Installation - Understanding the Different Types of Metal Cable Trays Available

| Type of Cable Tray | Material | Load Capacity (lbs) | Applications | Price Range ($) |

|---|---|---|---|---|

| Ladder Tray | Aluminum | 800 | Industrial, Data Center | 150 - 300 |

| Wire Mesh Tray | Steel | 750 | Commercial, Telecommunications | 100 - 250 |

| Solid Bottom Tray | Galvanized Steel | 1000 | Power Plant, High Voltage | 200 - 400 |

| Perforated Tray | Stainless Steel | 600 | Food Processing, Clean Rooms | 250 - 500 |

| Channel Tray | Aluminum | 500 | Commercial Buildings, Offices | 50 - 150 |

Evaluating Load Capacity and Weight Requirements for Cable Trays

When selecting a metal cable tray for electrical installations, evaluating the load capacity and weight requirements is crucial. The load capacity refers to the maximum weight the cable tray can support without compromising its structural integrity. It is essential to consider the total weight of all cables and additional equipment that will be housed within the tray. This includes not just the weight of the cables themselves, but also factors like mounting accessories and the potential for future expansions. Properly assessing these components can help prevent overloading, which might lead to failures or hazards.

Considering Installation Environment and Environmental Factors

In the context of offshore wind energy development, the choice of metal cable trays plays a crucial role in ensuring safe and efficient electrical installations. With increasing investments in renewable energy to combat climate change, it is essential to consider the installation environment and environmental factors when selecting cable trays. Research indicates that offshore installations must withstand harsh marine conditions, which include high humidity, saline exposure, and extreme wind forces. These factors can significantly influence the durability and longevity of cable management solutions.

According to a recent industry report, over 60% of electrical installation failures in marine environments are attributed to insufficient protective measures against corrosion and wear. Therefore, opting for cable trays made from materials with high corrosion resistance, such as stainless steel or specially coated metals, is critical. Moreover, the installation design must accommodate specific environmental challenges, such as temperature variations and potential chemical exposures from surrounding seawater, which can affect both the performance and safety of electrical systems. Careful consideration of these environmental aspects can enhance the reliability of offshore wind energy projects and support their sustainability goals.

Assessing Compliance with Electrical Codes and Safety Standards

When selecting the appropriate metal cable tray for electrical installations, it is paramount to assess compliance with electrical codes and safety standards, particularly in regards to fire safety. The choice of cable tray plays a crucial role in fire prevention and mitigation. It is important to ensure that the materials used meet relevant standards, such as those set by the National Fire Protection Association (NFPA) and local building regulations. These standards often dictate the thermal and structural integrity of the trays, which can significantly affect their performance under fire conditions.

Furthermore, understanding the specific requirements outlined in regional building codes is essential for effective electrical installations. Areas with stringent regulations may require specialized trays that offer enhanced fire resistance or are designed to contain and manage potential electrical faults. Using the CODE-ACCORD dataset as a reference can facilitate an informed decision-making process by providing insights into applicable regulations and safety measures that must be adhered to during installation. Compliance not only ensures safety but also contributes to the overall resilience of the electrical systems in the building.

Choosing the Right Accessories for Efficient Cable Tray System Installation

When selecting the right accessories for your cable tray system installation, it is crucial to focus on compatibility, efficiency, and future scalability. High-quality connectors and mounting hardware enhance the overall stability and performance of the tray, ensuring that it can handle the weight and organization of cables effectively. Accessories such as bends, tees, and braces should be chosen based on the specific layout of your installation to maximize space utilization while maintaining easy access for maintenance.

In addition, having modular accessories allows for flexibility in your installation. As technology evolves and systems expand, the ability to adapt your cable tray system becomes essential. Aim for accessories that not only meet current needs but also provide room for future upgrades. This foresight contributes to operational efficiency and long-term cost savings, ensuring that your cable management needs are met both now and in the years to come.

Related Posts

-

Exploring the Benefits and Innovations of Aluminum Cable Trays in Modern Electrical Installations

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

China Leads the Global Market with Best Cable Tray Covers for Unmatched Quality

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Emerging Technologies Shaping Best Cable Tray Systems for 2025 and How to Optimize Your Setup

-

Understanding Import and Export Certifications for the Best Stainless Steel Cable Tray