For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

How to Choose the Right Cable Tray for Your Electrical Project

In the realm of electrical installations, selecting the appropriate cable tray is crucial for ensuring both safety and efficiency. According to a report by the National Electrical Manufacturers Association (NEMA), improperly installed cable management systems can lead to increased maintenance costs and potential hazards, with as much as 30% of electrical failures attributed to inadequate cable support. As the demand for organized and secure cable management escalates in industrial, commercial, and residential projects, understanding the various types of cable trays available and their respective benefits is essential for electrical engineers and contractors.

The cable tray market is projected to grow significantly, driven by the increasing need for efficient electrical distribution systems. A report by MarketsandMarkets underscores that the global cable tray market is expected to reach $4.5 billion by 2025, exhibiting a compound annual growth rate (CAGR) of 5.8%. This surge highlights the importance of making informed decisions when it comes to selecting the right cable tray that not only meets regulatory standards but also aligns with the specific requirements of a project. By carefully considering factors such as material, load capacity, and installation environment, one can ensure a reliable and organized electrical infrastructure that enhances the overall performance of the system.

Understanding the Importance of Selecting the Right Cable Tray

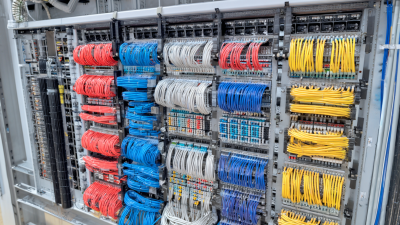

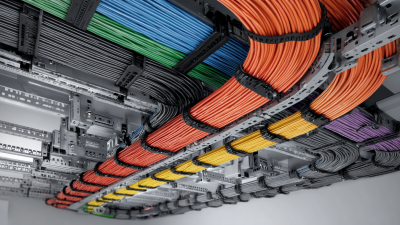

Selecting the right cable tray for your electrical project is crucial for several reasons. First and foremost, cable trays are essential for the organized management of electrical cables, providing both safety and efficiency in installation. By choosing an appropriate type, you can prevent cable damage, reduce the risk of electrical fires, and enhance the overall lifespan of the installation. The right tray supports optimal airflow around cables, which is vital for cooling, especially in environments with high heat loads.

Moreover, the material and design of the cable tray significantly influence its functionality and longevity. Factors such as load capacity, environmental conditions, and compatibility with existing infrastructure must be considered. For instance, using a galvanized steel tray in damp environments can mitigate corrosion issues, while non-metallic trays could be better suited for chemical resistance. By understanding the importance of these parameters, you ensure not only the effectiveness of your electrical installations but also compliance with safety standards and regulations.

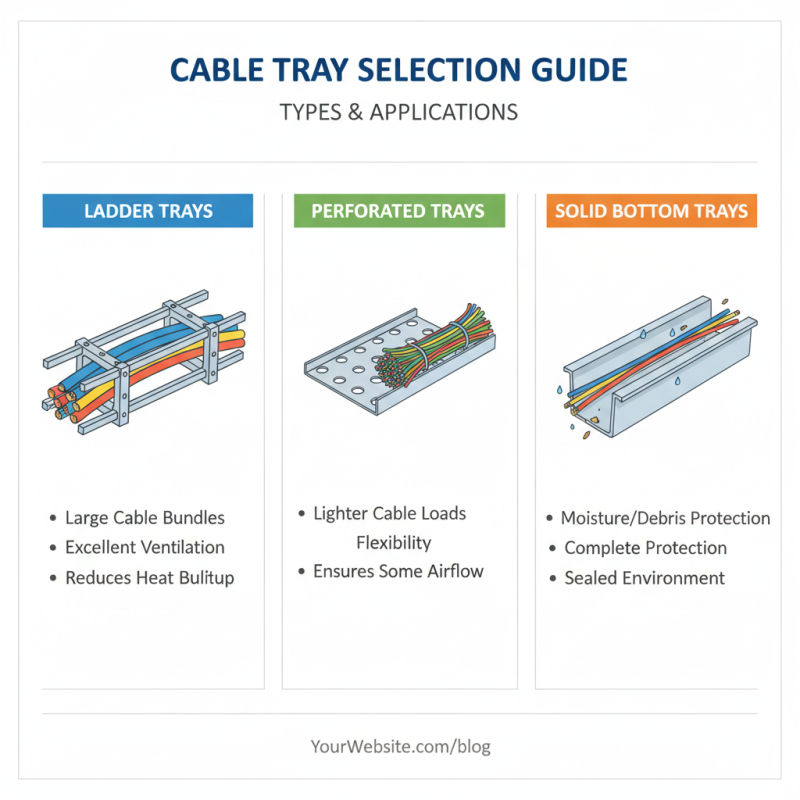

Types of Cable Trays and Their Suitable Applications

When selecting a cable tray for your electrical project, understanding the different types available and their suitable applications is essential. There are several common types of cable trays, including ladder trays, perforated trays, and solid bottom trays. Ladder trays are ideal for supporting larger bundles of cables, offering excellent ventilation and reducing heat buildup. On the other hand, perforated trays are suitable for lighter cable loads and provide flexibility while ensuring some airflow. Solid bottom trays are often used in environments where cables are exposed to moisture or debris, offering complete protection.

**Tips:** When choosing a cable tray, consider the environment it will be installed in. For areas with high moisture levels, opt for materials that resist corrosion, such as fiberglass or stainless steel. Additionally, think about future cable additions; selecting a design that allows easy access and modifications can save time and resources down the road.

Another important aspect to consider is the load capacity of the tray. Make sure to calculate the total weight of the cables and choose a tray that can support that weight comfortably. Overloading a cable tray can lead to safety hazards and increase maintenance costs. Always consult the manufacturer's specifications to ensure compliance with safety standards and local regulations.

Factors to Consider When Choosing a Cable Tray

When selecting the right cable tray for your electrical project, there are several crucial factors to consider. First, assess the environment where the cable tray will be installed. Industrial settings might require heavy-duty trays that can withstand harsh conditions, while residential or commercial projects may prioritize aesthetics and ease of installation. The U.S. cable tray market, valued at approximately USD 818.89 million in 2022, underscores the increasing importance of selecting the right tray, as its projected growth reflects the rising demand for efficient cable management solutions.

Another essential consideration is the tray's load capacity. Ensure the chosen tray can support the expected weight of cables, which can vary significantly based on the application. Furthermore, cable trays must comply with industry standards and regulations, which can vary by region. In the broader context, the global cable tray market, valued at $5.57 billion in 2024 and expected to reach $12.89 billion by 2032, indicates a growing recognition of the functional and safety aspects that cable trays provide in electrical project management.

Material Options for Cable Trays and Their Advantages

When selecting a cable tray for an electrical project, the choice of material plays a vital role in determining durability, cost-effectiveness, and suitability for the specific environment. Common materials used for cable trays include steel, aluminum, fiberglass, and PVC, each offering unique advantages.

Steel cable trays are renowned for their strength and load-bearing capacity, making them ideal for heavy-duty applications. They are often coated with hot-dip galvanization or paint to enhance corrosion resistance, ensuring they can withstand harsh conditions. Aluminum trays, on the other hand, are lightweight and resistant to corrosion, making them suitable for environments where rust is a concern. Their reduced weight can also lower installation costs.

Fiberglass and PVC cable trays provide excellent resistance to chemical exposure and moisture, making them ideal for industrial applications where corrosive substances are present. Additionally, fiberglass is non-conductive, thus promoting safety in electrical installations. Meanwhile, PVC trays are often more affordable and easier to install, making them an appealing choice for residential projects or less demanding commercial installations. Each material has its specific advantages, and the choice will ultimately depend on the project’s requirements and environmental factors.

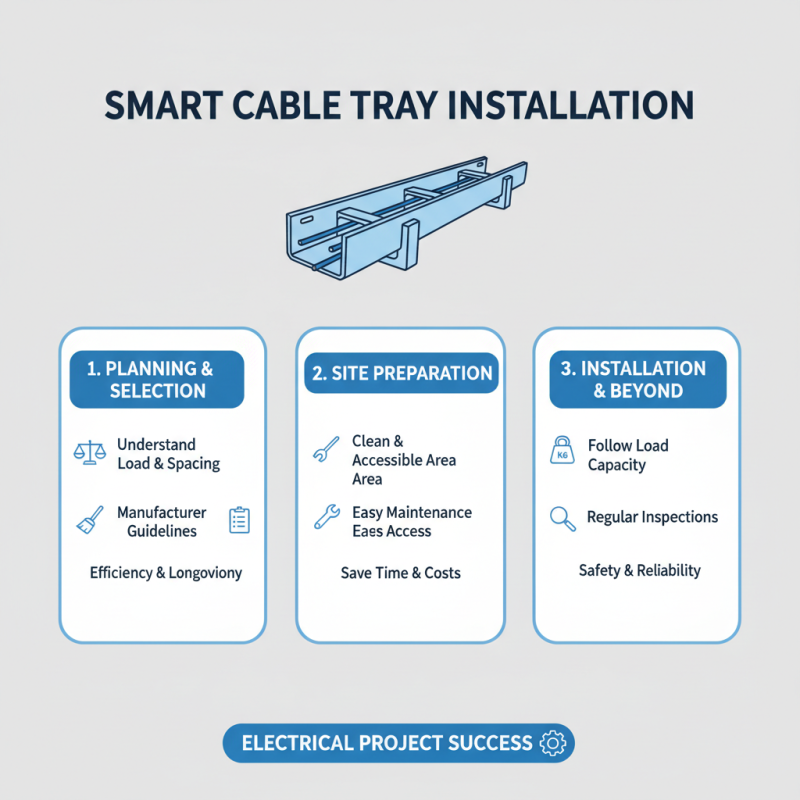

Installation Requirements and Maintenance for Cable Trays

When selecting the right cable tray for your electrical project, understanding installation requirements and maintenance is crucial for ensuring efficiency and longevity. Proper planning before installation can save time and costs. Ensure the site is clean and easily accessible, as cable trays should be installed in areas that allow for straightforward maintenance and adjustments. Always follow the manufacturer’s guidelines regarding load capacity and spacing to prevent potential hazards.

**Tips:** Use a laser level to ensure proper alignment and maintain a consistent height throughout the installation process. This will help in preventing strain on cables and facilitate easier access for maintenance.

Routine maintenance is vital to keep your cable trays functional. Regularly inspect them for any signs of wear, debris accumulation, or corrosion, especially in outdoor environments. Consider implementing a cleaning schedule to remove dirt and dust, which can hinder performance.

**Tips:** When performing inspections, use a checklist to ensure you don't overlook any potential issues. This can include checking for loose fittings, damage to the tray, or any environmental factors that could impact its integrity.

Related Posts

-

How to Choose the Right Cable Basket for Your Project

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

How to Choose the Best Wire Raceway for Your Electrical Needs and Efficiency

-

7 Essential Features of the Best Wire Raceway for Optimal Cable Management

-

Emerging Technologies Shaping Best Cable Tray Systems for 2025 and How to Optimize Your Setup