For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

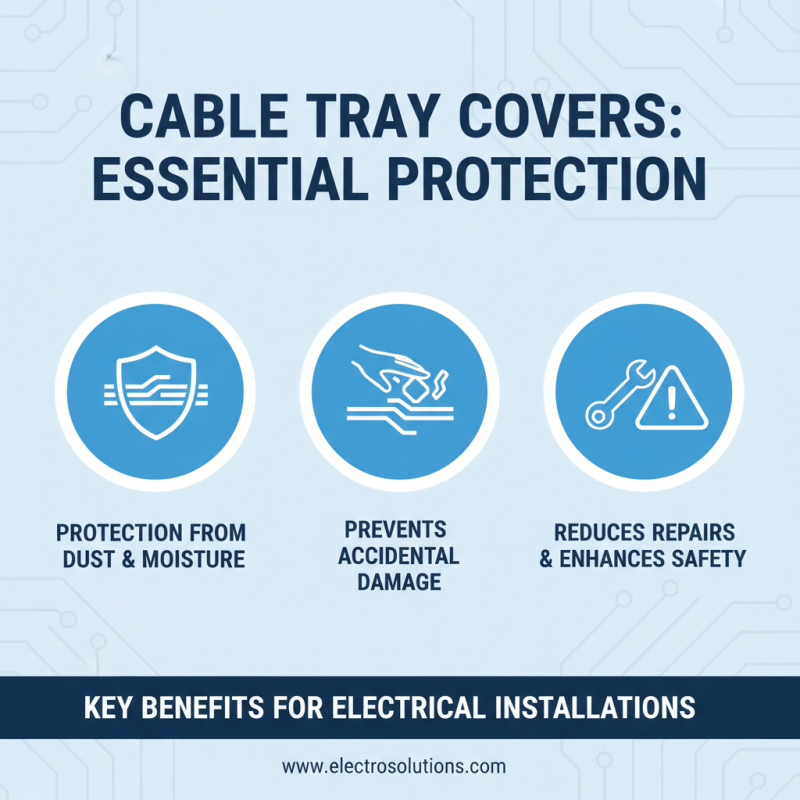

What is a Cable Tray Cover and Why is it Important?

In the world of electrical infrastructure, cable tray covers play a crucial role. These covers protect vital cables from environmental hazards and physical damage. According to a report by Research and Markets, the global cable management systems market is expected to reach $35 billion by 2025. The importance of cable tray covers lies not only in safeguarding cables but also in maintaining operational efficiency.

In various industries, the use of cable tray covers is essential for safety compliance. For instance, the National Fire Protection Association (NFPA) emphasizes the need for proper cable management to mitigate fire risks. However, many companies overlook this requirement, leading to potential hazards. The absence of cable tray covers can expose wires to dust, moisture, and mechanical stress, compromising system integrity.

Moreover, there is a growing trend toward adopting sustainable solutions. Innovative materials for cable tray covers can enhance durability while reducing environmental impact. Yet, organizations often struggle with balancing cost-effectiveness and quality. Reflecting on these challenges could lead to better decision-making regarding cable management practices.

What is a Cable Tray Cover?

A cable tray cover is an essential component in electrical installations. It serves as a protective barrier for cables laid within trays. These covers shield wires from dust, moisture, and accidental damage. Without proper covers, cables are exposed to various hazards. This could lead to costly repairs or even safety issues.

In many settings, cable tray covers come in different materials. Some are made of metal, offering durability. Others are plastic, providing lightweight options for easy handling. The choice of material matters. Poor selection might not ensure enough protection. For instance, a flimsy cover can wear down quickly, exposing the cables beneath. It’s a mistake that can compromise the entire system.

Proper installation of cable tray covers is crucial. They should fit securely without gaps. Otherwise, debris can find its way inside. Regular inspection is important, too. A person might overlook wear and tear until it’s too late. Reflecting on these aspects helps improve overall performance. Investing time in quality covers can prevent bigger problems down the line.

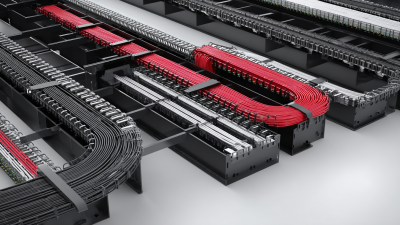

Types of Cable Tray Covers

Cable tray covers are essential in electrical installations. They provide protection for cables against dust, moisture, and physical damage. Different types of cable tray covers cater to various needs and environments. Selecting the right cover is crucial to ensure safety and efficiency in any project.

There are several types of cable tray covers. Solid covers are most common. They offer complete protection but can trap heat. This may lead to overheating. Perforated covers allow ventilation, which helps manage cable temperatures. These covers are suitable for environments with high heat generation. Lastly, half covers provide a balance. They shield cables while allowing some airflow. A 2022 industry report noted that improper cable management can increase maintenance costs by up to 30%.

When choosing a cover, consider the environment. Industrial settings often require robust materials, like stainless steel. In contrast, commercial buildings may opt for lighter materials. However, many users overlook the long-term impact. Many installations face challenges due to inadequate planning for cable management. This can lead to increased downtime and costs. Proper assessment before installation is necessary to avoid complications later.

Benefits of Using Cable Tray Covers

Cable tray covers serve a crucial role in protecting electrical and data cables. They shield wires from dust, debris, and physical damage. This protection helps ensure the longevity of the cables. In environments like factories or data centers, this is especially vital. Cables exposed to external elements can suffer failures over time.

Using cable tray covers can also enhance safety. They can prevent accidental contact with live wires. This reduces the risk of electrical shocks. Covers can be made from various materials, providing different levels of protection. Selecting the right material is key. It should resist fire, chemicals, or water, depending on the environment.

Additionally, cable tray covers contribute to organization. They tidy up cluttered installations. A messy workspace can lead to miscommunication and mistakes. When cables are properly managed, efficiency improves. Reflection on past experiences reveals the importance of prioritizing such details. Overlooking cable management can create bigger issues down the line.

Considerations for Choosing the Right Cable Tray Cover

When selecting a cable tray cover, several key elements must be considered to ensure optimal functionality. The material of the cover is crucial—options like aluminum, fiberglass, and steel each offer different benefits. According to the National Electrical Manufacturers Association, the right cover can reduce installation time by 30%. A durable cover protects cables from dust and moisture, extending their lifespan significantly.

Another important point is the size and design of the cover. The dimensions must fit the specific cable tray. An ill-fitting cover could lead to water ingress or debris accumulation. Inconsistent installation practices can compromise safety standards, leading to potential hazards. Industry studies reveal that improper cable management can increase maintenance costs by up to 40%. Therefore, investing time in choosing the right cover pays off over time.

Lastly, consider the environment where the cable tray will be placed. Covers designed for harsh conditions can prevent damage from chemicals or extreme temperatures. A report from the Electrical Safety Foundation International highlights that inadequate protection leads to higher failure rates in electrical systems. Thoughtful selection of a cable tray cover is not just about protection; it's about ensuring longevity and reliability.

Installation and Maintenance of Cable Tray Covers

Cable tray covers are crucial for protecting electrical installations. They help prevent dust, moisture, and debris from entering cable trays. In an industrial setting, approximately 28% of electrical failures are linked to environmental factors. Therefore, proper installation and maintenance of cable tray covers become essential.

Installation should follow industry guidelines. This includes ensuring that covers fit tightly over the trays. Gaps can allow contaminants to enter. Regular inspections are critical. One study revealed that 35% of cable tray issues stemmed from neglected maintenance. Cleaning the covers every few months is advisable, especially in dusty environments.

Training staff on the importance of proper handling is often overlooked. Many don’t realize that even a small crack can lead to significant damage. Awareness and routine checks can significantly enhance system reliability. Inadequate attention to these details can result in costly downtime. Prioritizing these small tasks ensures larger issues are avoided in the long run.

Related Posts

-

Ultimate Guide to Choosing the Best Wire Management Tray: Optimize Efficiency with Industry Insights

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Emerging Technologies Shaping Best Cable Tray Systems for 2025 and How to Optimize Your Setup

-

7 Essential Tips for Choosing the Right Cable Tray Systems for Your Project

-

Ultimate Guide to Electrical Cable Trays: Optimizing Efficiency and Safety in Modern Installations

-

7 Essential Tips for Choosing the Right Cable Tray Cover to Enhance Safety and Efficiency