For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

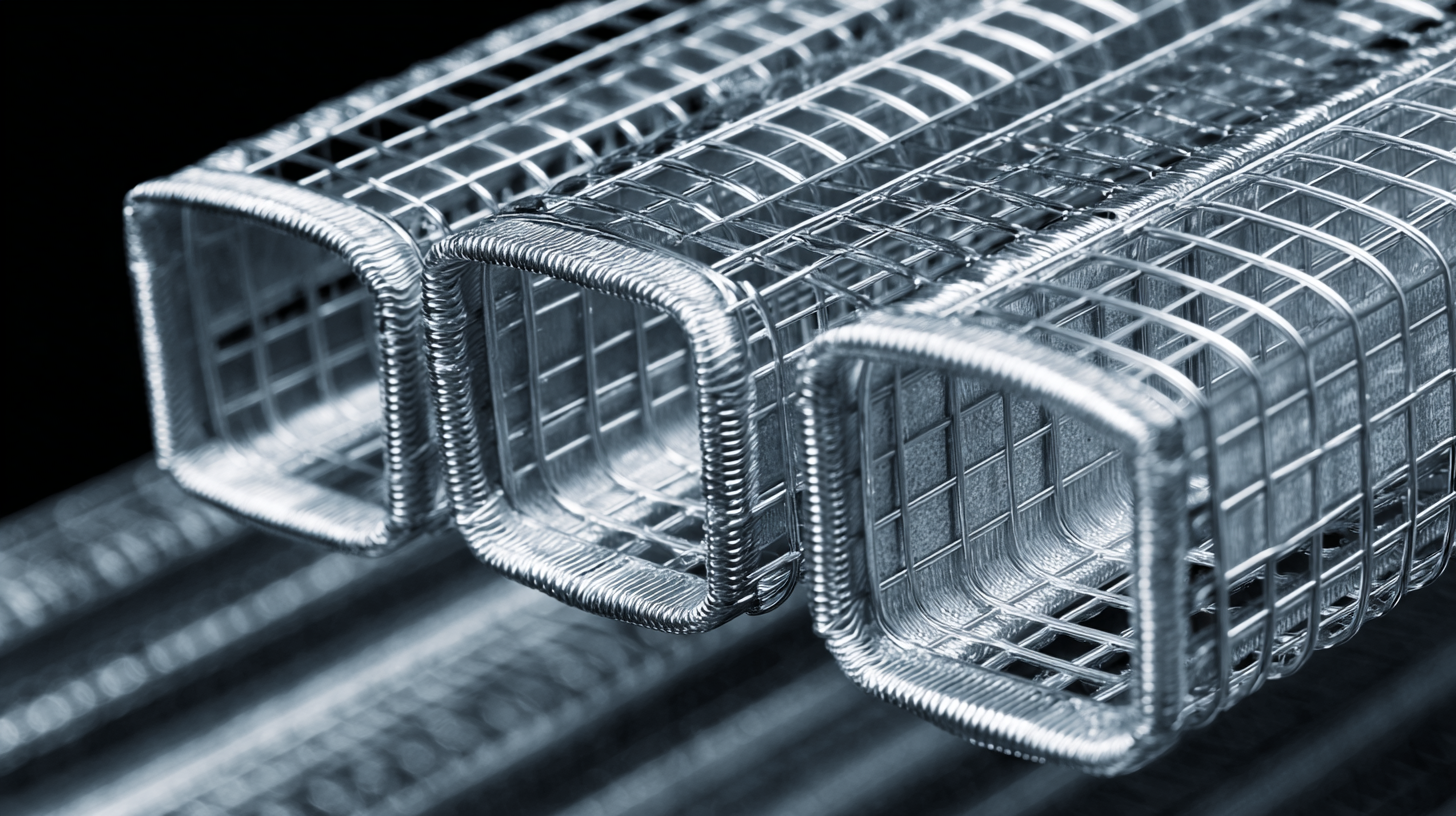

Craftsmanship from China Redefining Global Standards for Best Wire Mesh Cable Trays

The rise of craftsmanship from China has significantly influenced global manufacturing standards, particularly in the production of wire mesh cable trays. According to a recent industry report by MarketsandMarkets, the global cable tray market is projected to reach $5.48 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.3%. This growth underscores the increasing demand for efficient and durable cable management solutions across various sectors, including construction, telecommunications, and industrial applications.

Chinese manufacturers are at the forefront of this evolution, applying precision engineering and innovative designs to wire mesh cable trays, ensuring they meet the highest international standards. As cities and industries embrace advanced technologies, the need for reliable infrastructure becomes paramount, positioning wire mesh cable trays as essential components in effective cable management systems, thus re-defining industry benchmarks and expectations.

The Evolution of Wire Mesh Cable Trays: A Global Perspective

The evolution of wire mesh cable trays has been significant, reflecting the technological advancements and changing demands of the global market. According to a recent report by Mordor Intelligence, the global wire mesh cable tray market was valued at approximately $1.5 billion in 2021 and is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2022 to 2027. This growth is largely driven by the increasing need for efficient cable management systems in various industries, including telecommunications and data centers, which require robust and versatile solutions for managing their extensive wiring networks.

China, as a major player in this evolving landscape, has set new benchmarks for craftsmanship and innovation in wire mesh cable trays. Chinese manufacturers are utilizing advanced materials and production techniques that enhance the durability and flexibility of these trays. Research from Research and Markets indicates that wire mesh trays are now preferred over traditional solid trays due to their lightweight nature and ability to allow air circulation, which helps in cooling systems. This paradigm shift is reshaping global standards, making Chinese products an attractive choice for international projects seeking cost-effective and efficient cable management solutions.

Craftsmanship from China Redefining Global Standards for Wire Mesh Cable Trays

This chart illustrates the production volume of wire mesh cable trays across different regions, showcasing the significant contributions of China in the global market.

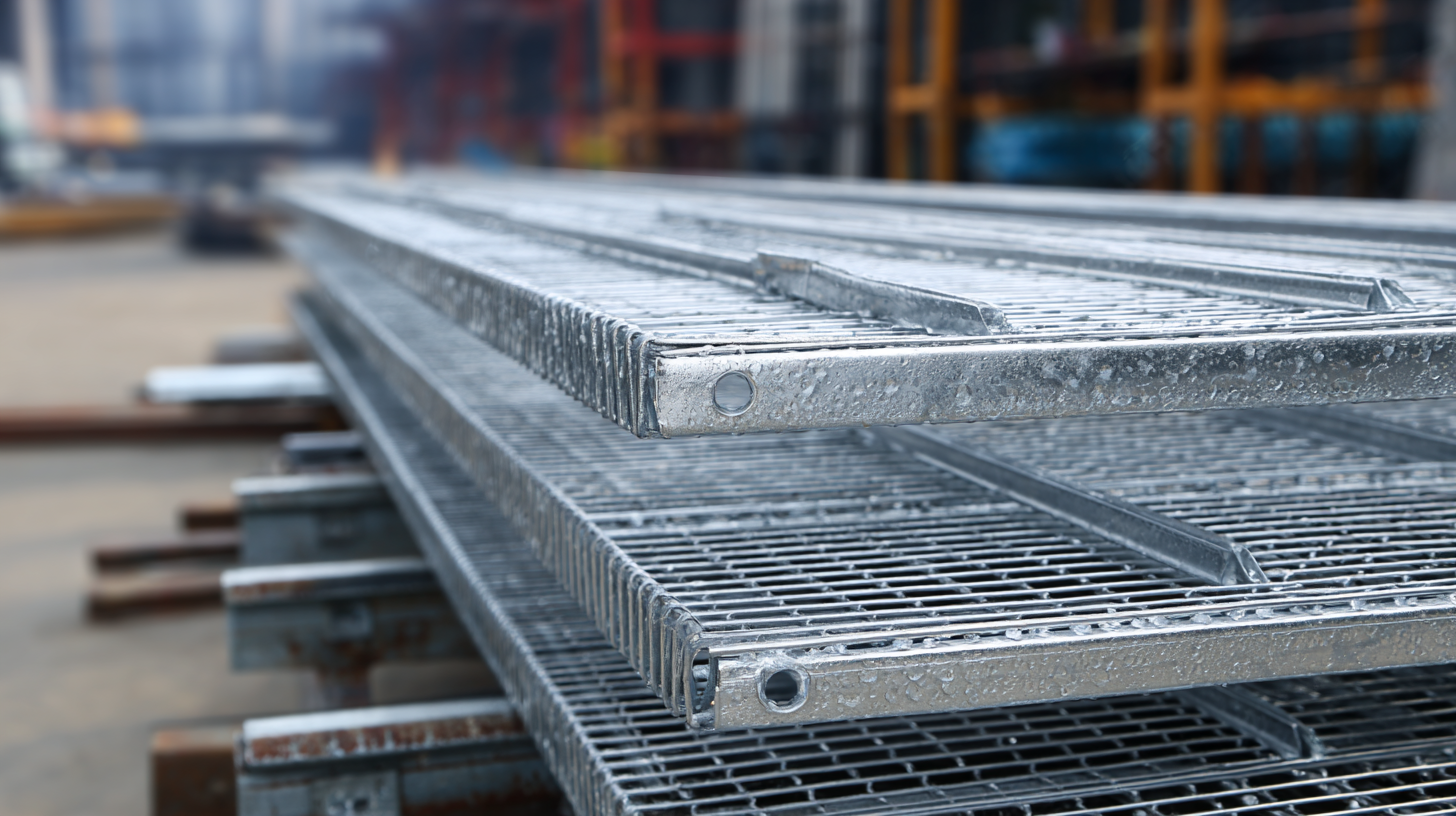

China's Role in Setting New Standards for Cable Management Solutions

As the demand for efficient cable management solutions grows, China's influence in the industry has become increasingly pronounced. With a focus on high-quality craftsmanship and innovative designs, Chinese manufacturers are redefining the global standards for wire mesh cable trays. This shift not only enhances the aesthetic appeal of installations but also ensures improved durability and functionality, meeting the diverse needs of various industries worldwide.

When selecting a wire mesh cable tray, it’s essential to consider the materials used. Opt for trays made from corrosion-resistant steel or aluminum to ensure longevity, particularly in environments exposed to moisture or chemicals. Additionally, check for design features that facilitate easy installation and expansion, accommodating future growth in cabling needs without requiring a complete overhaul.

Moreover, alignment with international standards is critical. Manufacturers in China are increasingly adopting global certifications, which not only boosts their credibility but also assures customers of product reliability and safety. For an optimal installation experience, always verify that the cable trays meet local regulations and industry guidelines, ensuring compliance and performance across your projects.

Key Industry Statistics: Demand and Growth Trends in Wire Mesh Cable Trays

The wire mesh cable tray industry has been experiencing significant growth, driven by an increasing demand for efficient cable management solutions across various sectors. Key industry statistics reveal that the global wire mesh cable trays market is poised for expansion, with projections indicating a compound annual growth rate (CAGR) of around 5% over the next five years. This growth can largely be attributed to the rising adoption of advanced technologies in construction and electrical installations, where the need for reliable and organized cable management is paramount.

Additionally, the proliferation of infrastructure development projects worldwide has further amplified the need for high-quality wire mesh cable trays. With manufacturers in China leading the charge, the emphasis on craftsmanship and quality has begun to set new global standards. As companies increasingly prioritize sustainability and efficiency, the adoption of wire mesh trays—known for their durability and ease of installation—continues to gain traction. In markets where traditional cable management systems have dominated, there is now a growing awareness of the benefits offered by innovative wire mesh solutions, positioning them as a preferred choice for both new constructions and retrofitting projects.

Craftsmanship from China Redefining Global Standards for Best Wire Mesh Cable Trays

| Region | Market Size (USD Million) | Annual Growth Rate (%) | Key Drivers |

|---|---|---|---|

| North America | 450 | 5.0% | Infrastructure development, Industrial output growth |

| Europe | 350 | 4.5% | Regulatory standards, Renewable energy projects |

| Asia-Pacific | 600 | 7.5% | Rapid industrialization, Urbanization |

| Latin America | 150 | 3.5% | Economic recovery, Investment in transportation |

| Middle East & Africa | 200 | 6.0% | Oil & gas projects, Infrastructure expansion |

Innovative Techniques in Manufacturing: The Chinese Craftsmanship Advantage

China's craftsmanship is making waves in the manufacturing landscape, especially when it comes to wire mesh cable trays. Innovative techniques developed by skilled artisans have not only improved product durability but also enhanced functionality to meet global standards. These advancements stem from a deep-rooted understanding of materials and state-of-the-art technology, allowing for more efficient production processes and cost-effective solutions.

Tips for ensuring quality in wire mesh cable tray manufacturing include focusing on material selection and manufacturing techniques. Opt for high-grade raw materials that can withstand environmental stress, as this ensures longevity. Additionally, incorporating automated technology and precise welding methods can significantly boost production efficiency while maintaining high-quality standards. Implementing these practices will help businesses stay competitive in the global market.

Another essential tip is to continuously invest in research and development. Staying ahead in the industry requires adapting to changing demands and exploring new techniques. By fostering innovation, manufacturers can not only improve their products but also set new benchmarks within the industry, further solidifying their reputation as leaders in craftsmanship.

Comparative Analysis: Chinese versus Global Wire Mesh Cable Tray Quality Standards

The global landscape of wire mesh cable trays is undergoing a significant transformation, with China's craftsmanship setting new benchmarks for quality and durability. A comparative analysis reveals that while traditional players in the market maintain stringent quality standards, Chinese manufacturers are innovating rapidly to meet and exceed these expectations. This shift is primarily driven by advancements in technology and a commitment to quality materials, leading to products that are both cost-effective and resilient.

Furthermore, Chinese wire mesh cable trays have begun to align closely with international standards, demonstrating their commitment to global quality benchmarks. The integration of modern manufacturing techniques has allowed for enhanced load-bearing capacities and resistance to corrosion, crucial elements for installations in various environments. As a result, industry stakeholders are beginning to recognize the merit in sourcing from Chinese suppliers, not just for competitive pricing but also for superior quality that meets or surpasses traditional global standards. This integration reflects a growing trend where quality is becoming a universal language, redefining success in the global marketplace.