For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

How to Choose the Right Aluminum Cable Tray for Your Project Needs

Choosing the right aluminum cable tray for your project needs is a critical decision that can greatly influence the efficiency and safety of your electrical installations. According to a recent industry report by MarketsandMarkets, the global cable tray market is projected to reach $6.3 billion by 2025, with aluminum cable trays accounting for a significant share due to their lightweight, corrosion-resistant properties and ease of installation.

Moreover, the increasing demand for organized cable management solutions in commercial and industrial sectors further underscores the importance of selecting the appropriate cable tray system. As projects become more complex with the integration of advanced technologies, understanding the specifications and applications of aluminum cable trays is essential for ensuring optimal performance and compliance with safety standards.

This guide will help you navigate the selection process to find the perfect aluminum cable tray for your specific requirements.

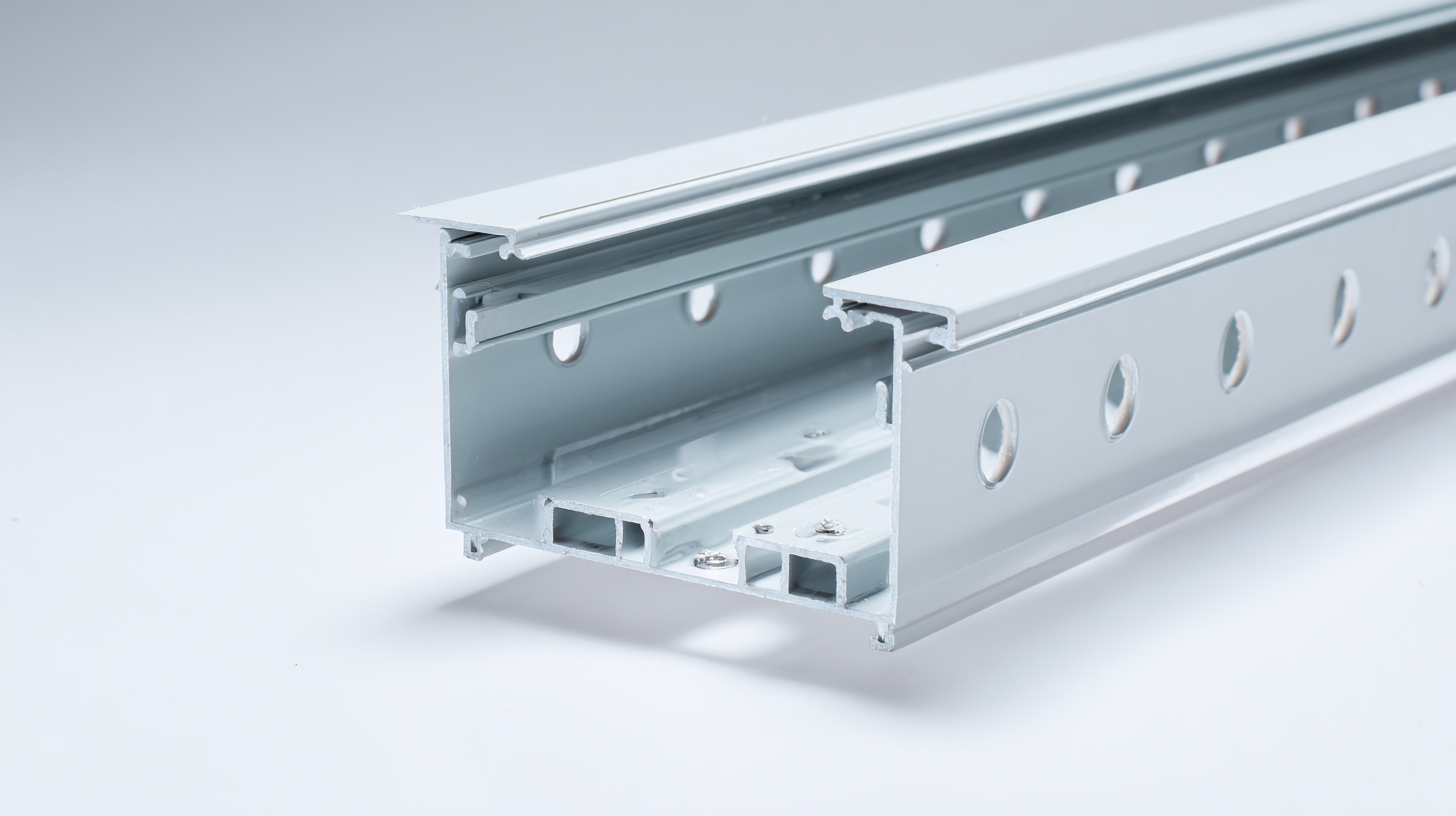

Understanding the Different Types of Aluminum Cable Trays Available

When selecting an aluminum cable tray for your project, it's essential to understand the different types available, as they cater to various applications and environments. Common options include ladder trays, channel trays, and wire mesh trays. Ladder trays are ideal for heavy cable loads and provide excellent ventilation, while channel trays offer a more enclosed option, suitable for protecting cables from moisture and physical damage. Wire mesh trays, on the other hand, are lightweight and promote airflow, making them perfect for data centers where heat dissipation is critical.

Additionally, consider the specific installation environment. For outdoor or industrial settings, corrosion-resistant aluminum trays are essential to ensure durability. If your project requires frequent access to cables, choose a type that allows for easy installation and maintenance, such as those with removable covers. Evaluating the weight capacity and size specifications of each tray type will also help you make an informed decision, ensuring that your chosen cable management solution meets the demands of your project efficiently.

Aluminum Cable Tray Types and Their Popularity

Assessing Load Capacity and Environmental Conditions for Cable Trays

When selecting an aluminum cable tray, it is crucial to assess both the load capacity and the environmental conditions in which it will be installed. The load capacity of a cable tray directly influences its performance; for instance, a cable tray's ability to support multiple cables without compromising safety is critical, especially in demanding environments like data centers, where substantial power demands and high heat loads are commonplace. Industry reports indicate that the global FRP cable tray market is projected to grow from $253.48 million in 2019 to approximately $696.78 million by 2032, signifying a compound annual growth rate (CAGR) of 8.36%. This growth underlines the increasing importance of selecting the right materials and designs to withstand heavier and more complex cabling systems.

Moreover, environmental conditions such as temperature, humidity, and potential exposure to corrosive elements must influence the selection process. Recent studies emphasize the importance of considering these conditions to ensure optimal thermal performance and longevity of the cable tray. For example, research on the thermal assessment of power cables highlights how environmental factors can affect current ratings, influencing overall system performance. Understanding the relation between load strength and stiffness in cable trays is equally crucial; this ratio can dictate not only the tray's ability to support the cables deployed but also its durability over time, especially in challenging environments. Hence, thorough evaluation of these technical parameters is essential to ensure reliability and efficiency in cable management systems.

Evaluating Installation Requirements and Space Constraints

When selecting an aluminum cable tray, one of the most critical factors to consider is the installation requirements. Determine how many cables you need to accommodate, as well as their sizes and types. Understanding the weight and load capacities of the cable tray is vital. Ensure that the chosen tray can support the total load without compromising its integrity or safety. Additionally, assessing accessibility during maintenance is crucial; the tray should allow for easy access to cables without significant disruption.

Space constraints also play a pivotal role in the selection process. Analyze the physical dimensions of the installation area, including height, width, and length. In tight spaces, a tray with a low profile or versatile mounting options may be necessary. Moreover, consider the layout of existing structures and any potential obstructions. An effective aluminum cable tray system should fit seamlessly into the available space while meeting local codes and regulations. Balancing installation requirements with space limitations ensures a functional and safe cable management solution for any project.

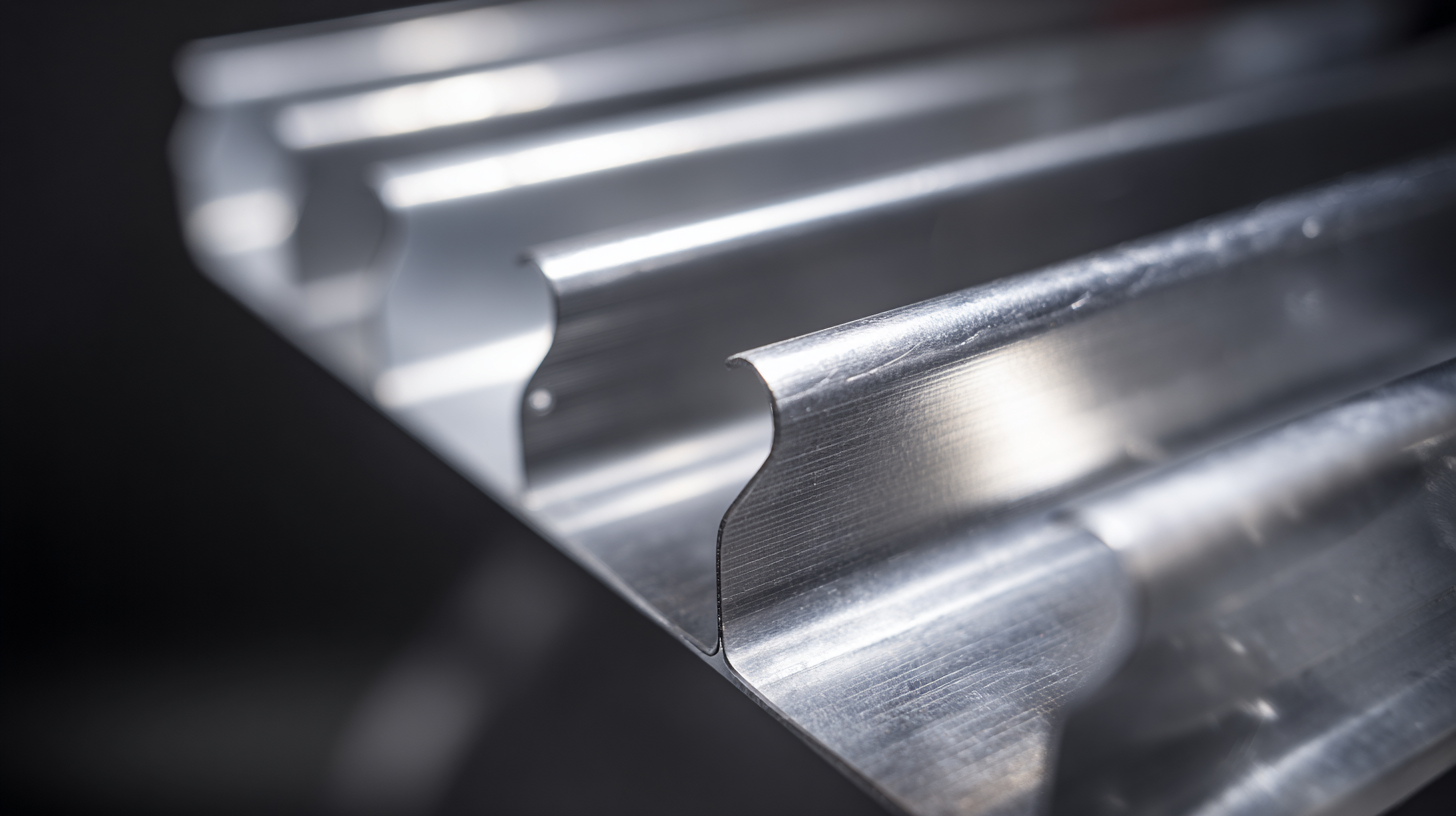

Considering Corrosion Resistance and Maintenance Needs

When selecting the right aluminum cable tray for your project, it is crucial to consider corrosion resistance and maintenance needs. Corrosion can impose a significant economic burden, with direct costs projected to reach $4 trillion globally by 2025, representing approximately 2% to 5% of global GDP. This underscores the importance of investing in materials and solutions that can withstand harsh environments and maintain their integrity over time.

The global anticorrosion coatings market was valued at $38.13 billion in 2024, with expectations to grow further due to heightened awareness of the challenges posed by corrosion. Among these advanced solutions, aluminum cable trays often provide a favorable resistance to corrosion when compared to traditional materials. Moreover, the corrosion monitoring market is predicted to grow significantly, driven by the integration of AI-based detection systems, reflecting a broader trend towards smarter and more efficient maintenance practices in industrial settings. By selecting aluminum cable trays that incorporate these advanced coatings and monitoring technologies, project managers can better mitigate the risks associated with corrosion and reduce long-term maintenance costs.

Budgeting for Quality vs. Cost in Aluminum Cable Tray Selection

When selecting an aluminum cable tray for your project, it's essential to strike the right balance between quality and cost. Investing in high-quality materials can lead to long-term benefits such as durability, resistance to corrosion, and lower maintenance costs. However, project budgets often constrain our options, which makes it crucial to prioritize features that align with your specific needs.

When selecting an aluminum cable tray for your project, it's essential to strike the right balance between quality and cost. Investing in high-quality materials can lead to long-term benefits such as durability, resistance to corrosion, and lower maintenance costs. However, project budgets often constrain our options, which makes it crucial to prioritize features that align with your specific needs.

Tips: Focus on understanding the environmental conditions the cable tray will face. If your tray will be exposed to harsh weather or chemicals, selecting a more durable option could save money in the long run, even if the initial cost is higher. Additionally, consider the load capacity requirements carefully, ensuring you choose a tray that can handle your cable weight without compromising its integrity.

Another essential consideration is manufacturer reputation. Opting for well-reviewed and established brands may come at a higher cost initially, but investing in a reputable product often guarantees better performance and reliability. Furthermore, this approach may offer the added benefit of longer warranties, providing more peace of mind as you manage your project's budget effectively.

Related Posts

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Understanding Import and Export Certifications for the Best Stainless Steel Cable Tray

-

Ultimate Guide to Electrical Cable Trays: Optimizing Efficiency and Safety in Modern Installations

-

The Future of Ladder Cable Tray Innovation in Electrical Infrastructure

-

How to Choose the Right Ladder Tray for Your Electrical Installation Needs