For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

How to Choose the Right Cable Basket for Your Project

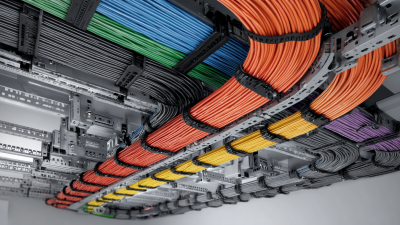

Selecting the right cable basket for your project is a critical decision that impacts both the organization and efficiency of your cable management system. Whether you're working on a large-scale industrial installation or a smaller commercial project, understanding the various types of cable baskets is essential for achieving optimal performance and safety. A well-chosen cable basket not only supports the weight of cables but also allows for effective airflow, reducing the risk of overheating and ensuring compliance with electrical codes. In this guide, we will explore key factors to consider when choosing a cable basket, including materials, size, load capacity, and installation requirements. By taking these elements into account, you can make an informed decision that enhances the functionality of your project while providing long-lasting support for your cabling needs.

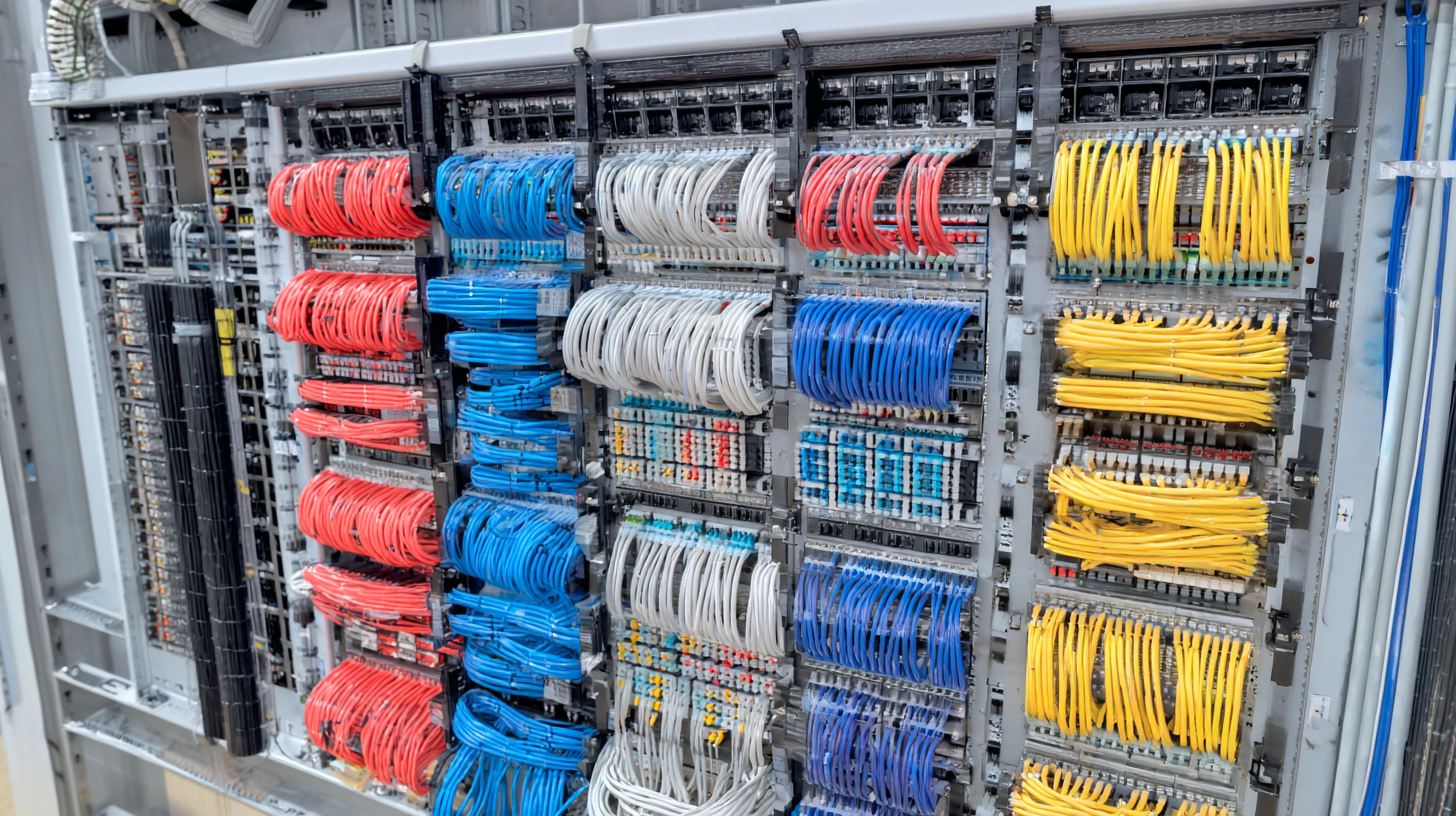

Understanding the Different Types of Cable Baskets Available on the Market

When selecting the right cable basket for your project, understanding the various types available on the market is essential. Cable baskets come in several materials and designs, each serving different purposes depending on the environment and usage requirements. For instance, metal cable baskets are often favored for their strength and durability, making them ideal for industrial settings. Alternatively, FRP (Fiber Reinforced Plastic) cable trays are gaining popularity due to their lightweight nature and resistance to corrosion, which makes them suitable for outdoor installations or areas where chemical exposure is a concern.

**Tips:** Consider the load capacity and maximum weight your cable basket will need to support. This will help you determine not only the material but also the design that suits your project best. Additionally, think about the installation space—some cable baskets are more compact and easier to install in tight areas, while others are designed for larger setups.

When assessing your options, also look at the growth trends in the cable management market, as advancements in design can affect both functionality and aesthetics. Newer solutions may offer better organization features, making it easier to maintain and manage cables in both residential and commercial settings. Evaluating these factors will ultimately aid you in choosing the optimal cable basket for your specific needs.

How to Choose the Right Cable Basket for Your Project

Assessing Project Requirements for Cable Management Solutions

When embarking on a project that requires cable management, it's essential to assess the specific requirements first. Understanding the scale and complexity of your installation can significantly influence your choice of cable basket. Consider factors such as the type of cables you will be using, the installation environment, and any regulatory standards that may apply. For instance, heavy-duty cables will necessitate a sturdier basket, while installations in wet or corrosive environments may require baskets made from specific materials that offer durability and weather resistance.

Tips: Evaluate the cable load and organize cables by function, which can help in selecting the appropriate size and style of cable basket. Additionally, remember that proper airflow around the cables is crucial to prevent overheating. Ensure that the basket has adequate ventilation if your project involves high-temperature cables.

Furthermore, think about accessibility and future expansions. Choosing a cable basket that allows easy access for maintenance while providing room for additional cables can save time and costs in the long run. Investing in baskets with modular designs can offer flexibility, enabling adjustments as project needs evolve.

Evaluating Material Options for Durability and Performance

When selecting the right cable basket for your project, evaluating material options is essential for ensuring durability and performance. Cable baskets are typically made from materials such as steel, aluminum, and plastic, each with unique advantages and drawbacks. According to a recent report by the National Electrical Manufacturers Association (NEMA), steel cable baskets offer superior strength and weight-bearing capabilities, making them ideal for heavy-duty applications. They are often hot-dipped galvanized or powder-coated, providing excellent corrosion resistance in challenging environments.

On the other hand, aluminum cable baskets weigh significantly less, which can reduce installation costs and labor. The Aluminum Association found that aluminum baskets can maintain structural integrity while being 50% lighter than comparable steel options. This can be particularly beneficial in projects where mobility and ease of installation are critical. Additionally, plastic cable trays offer corrosion resistance and are often used in environments prone to chemical exposure. Industry analysis indicates that while plastic baskets may have lower mechanical strength, they can offer significant savings on maintenance in specific applications. Therefore, choosing the right material involves a careful assessment of the project's specific requirements and environmental conditions.

Determining the Appropriate Size and Capacity for Cable Baskets

Choosing the right cable basket for your project involves understanding the appropriate size and capacity to meet your specific needs. The first step is to accurately assess the volume of cables you anticipate needing to accommodate. Measure not only the current quantity of cables but also consider future expansion. Overloading a basket can lead to cable damage and compromised organization, so ensure you factor in any necessary allowances for growth.

Next, evaluate the physical constraints of your installation site. The cable basket should fit within the available space without impeding other systems. Consider the dimensions and layout, making sure to account for any bends or turns in the wiring paths. It's also important to choose a basket that is constructed from suitable materials to support the weight and environmental factors, such as moisture or temperature variations. By carefully determining both the size and capacity, you can select a cable basket that optimally supports your project's requirements.

Budget Considerations: Balancing Cost and Quality in Your Selection

When selecting a cable basket for your project, budget considerations play a crucial role. Balancing cost and quality can be a challenging task, but it’s essential to ensure the longevity and reliability of your installation. Low-priced options may seem appealing initially, but they often compromise on material durability and design efficiency. Investing in a high-quality cable basket can save you money in the long run by minimizing the need for replacements and repairs.

When selecting a cable basket for your project, budget considerations play a crucial role. Balancing cost and quality can be a challenging task, but it’s essential to ensure the longevity and reliability of your installation. Low-priced options may seem appealing initially, but they often compromise on material durability and design efficiency. Investing in a high-quality cable basket can save you money in the long run by minimizing the need for replacements and repairs.

Tip: Always assess the specifications and certifications of the cable baskets you are considering. This can help you identify which products offer the best value for your investment. For example, look for baskets made from corrosion-resistant materials, which may be priced higher but can outperform cheaper alternatives in demanding environments.

Another important aspect to keep in mind is scalability. Choosing a cable basket that allows for future expansions or modifications can be a worthwhile investment. Evaluate your project requirements and consider potential growth when making your decision.

Tip: Opt for modular designs that can easily adapt to changes in cable management needs. This flexibility can prevent additional costs down the road, making a seemingly expensive choice actually more economical in the context of your project’s lifecycle.

Related Posts

-

How to Choose the Right Ladder Tray for Your Electrical Installation Needs

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

7 Essential Features of the Best Wire Raceway for Optimal Cable Management

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

The Future of Ladder Cable Tray Innovation in Electrical Infrastructure

-

How to Choose the Best Wire Raceway for Your Electrical Needs and Efficiency