For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

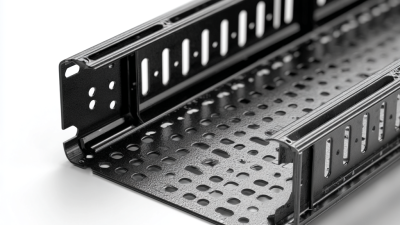

How to Choose the Right Ladder Tray for Your Electrical Installation Needs

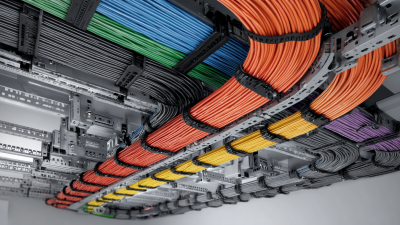

In the fast-evolving electrical installation industry, selecting the appropriate ladder tray is crucial for ensuring safety, efficiency, and long-term reliability. According to a report by Research and Markets, the global cable management market, which includes ladder trays, is projected to reach $15 billion by 2025, driven by increasing demand for organized wiring solutions in commercial and industrial sectors. Ladder trays not only provide structural support for cables but also facilitate proper ventilation and accessibility, thereby extending the lifespan of electrical systems. With various materials, sizes, and designs available, it can be challenging to determine which ladder tray best suits your specific requirements. This blog aims to guide you through the essential considerations when choosing the right ladder tray for your electrical installation needs, ensuring compliance with relevant standards and maximizing efficiency.

Understanding Ladder Tray Types: An Overview

When considering electrical installations, selecting the right ladder tray is crucial. Ladder trays come in various types, each designed to accommodate specific application needs. Understanding these types is essential for ensuring effective cable management and compliance with industry standards. Recent market reports highlight that the global cable tray market was valued at approximately USD 4.2 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) exceeding 6.8% from 2024 to 2032. This growth reflects the increasing demand for efficient cable management solutions across various sectors.

Among the leading developments in this market is the launch of advanced cable tray systems that streamline installation processes. For instance, innovative solutions that meet NEMA requirements have been introduced, allowing for modifications on-site, thereby reducing labor hours and installation costs significantly. With such advancements, businesses can choose ladder trays that not only support their electrical installations but also enhance the overall efficiency of their projects, adapting to evolving technological requirements and industry standards.

Types of Ladder Trays Used in Electrical Installations

Key Factors to Consider When Selecting Ladder Trays

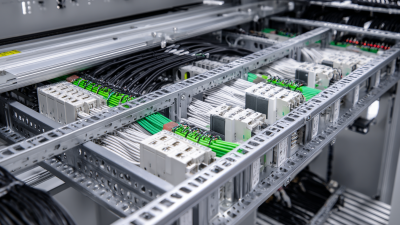

When selecting a ladder tray for your electrical installation, several key factors must be considered. First, the load capacity is critical. According to the National Electrical Manufacturers Association (NEMA), ladder trays should be able to safely support the weight of cables and additional accessories, typically ranging from 50 lbs to over 500 lbs per linear foot, depending on the application. Make sure to choose a tray that not only meets your current needs but also allows for future expansion.

Material is another crucial factor. Fiberglass and aluminum are popular choices due to their corrosion resistance and durability. The market research from Global Market Insights indicates that the demand for aluminum ladder trays is expected to grow by 5.5% annually, highlighting their increasing popularity in various installations. Additionally, consider the environmental conditions where the tray will be installed, as exposure to chemicals or high temperatures can necessitate specialized materials.

Tips: Always validate the manufacturer's specifications and ensure that the tray complies with local codes and regulations. Furthermore, conducting a thorough site assessment can help identify specific installation challenges that may require custom solutions. Don't forget to evaluate installation ease and accessibility for future maintenance, which can save time and costs down the line.

Comparing Material Options for Ladder Trays: Steel vs. Aluminum

When it comes to selecting the right ladder tray for electrical installations, the choice between steel and aluminum material is critical. Steel ladder trays are renowned for their exceptional strength and durability, making them ideal for heavy-duty applications. They can withstand high loads and harsh environments, making them suitable for industrial settings where resilience is paramount. However, steel trays are often heavier, which could pose challenges during installation and may require additional support structures.

On the other hand, aluminum ladder trays offer a lightweight alternative that is easier to handle and install. They also have excellent corrosion resistance, making them suitable for environments where moisture or chemicals may be present. While aluminum trays may not support as much weight as their steel counterparts, they are often chosen for their versatility and lower long-term maintenance costs. Ultimately, the decision between steel and aluminum should consider the specific requirements of the installation site, including weight capacity, environmental conditions, and installation ease.

How to Choose the Right Ladder Tray for Your Electrical Installation Needs - Comparing Material Options for Ladder Trays: Steel vs. Aluminum

| Feature | Steel Ladder Tray | Aluminum Ladder Tray |

|---|---|---|

| Weight | Heavier | Lighter |

| Corrosion Resistance | Lower | Higher |

| Cost | Generally lower | Generally higher |

| Mechanical Strength | Higher | Lower |

| Installation Difficulty | More difficult due to weight | Easier to handle |

| Temperature Resistance | Better resistance | Good but lower than steel |

Sizing and Load Capacity: What You Need to Know

When selecting a ladder tray for your electrical installation, understanding sizing and load capacity is crucial. The size of the tray should correspond to the amount of cabling you plan to install. It's important to account for both current and future needs, as underestimating capacity can lead to complications down the line. A general guideline is to allow for 50% more space than currently required, ensuring that additional cables can be added without the need for a complete system overhaul.

Tips:

1. Always refer to manufacturer specifications for exact dimensions and load ratings; this ensures safety and compliance with local codes.

2. Consider the weight of the cables when evaluating load capacity. Ladder trays come with different load ratings, so it's essential to choose one that exceeds the weight of the installed cables along with any potential growth.

3. If you're uncertain about the load capacity or sizing, consult with a professional electrician. They can provide insights based on your specific environment and usage requirements.

Proper sizing and understanding of load capacity will not only enhance the safety of your installation but also optimize performance and longevity.

Installation and Maintenance Tips for Ladder Tray Systems

When it comes to the installation and maintenance of ladder tray systems, understanding best practices can significantly enhance performance and longevity. According to a report by the National Electrical Contractors Association (NECA), improper installation can lead to a 25% increase in maintenance costs over the system's lifecycle. To avoid this, ensure that the ladder tray is installed on a stable structure, following all local electrical codes, and that load capacities are respected based on the manufacturer's specifications.

Maintenance is equally crucial. Regular inspections should be conducted at least bi-annually, focusing on potential corrosion and structural integrity, particularly in industrial environments where exposure to harsh chemicals is common. The National Fire Protection Association (NFPA) suggests that maintaining clear access to the trays and ensuring proper cable management can prevent accidents and system failures. By adhering to these guidelines, facilities can enhance the reliability of their electrical installations while minimizing unnecessary risks and expenses.

Related Posts

-

7 Essential Features of the Best Wire Raceway for Optimal Cable Management

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

How to Choose the Best Wire Raceway for Your Electrical Needs and Efficiency

-

China Leads the Global Market with Best Cable Tray Covers for Unmatched Quality

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Innovative Solutions for Cable Management Issues in Power Plant Applications Using Best Wire Tray