For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

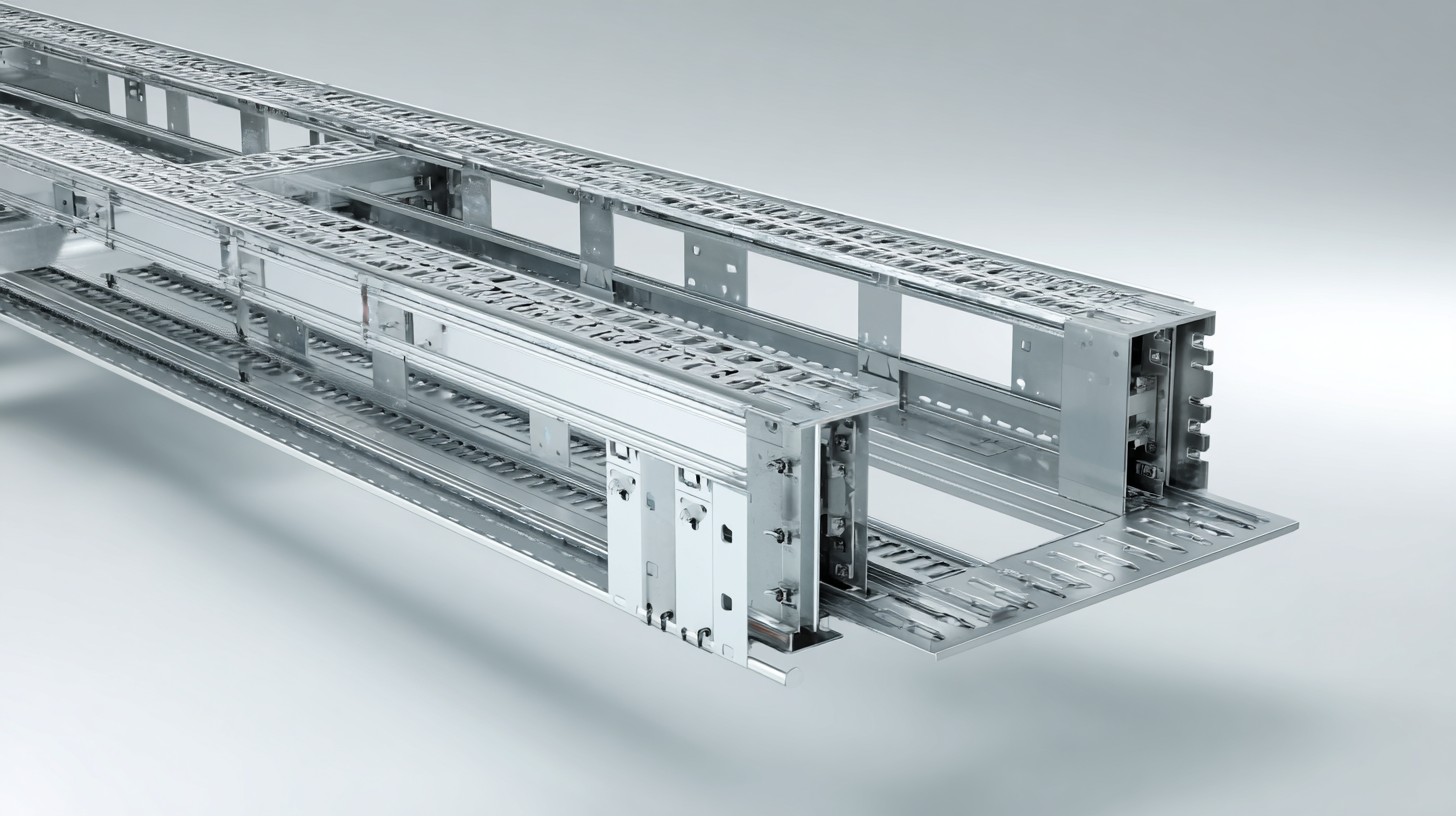

Choosing the Right Metal Cable Tray for Your Specific Needs

When it comes to organizing and protecting electrical cables, choosing the right metal cable tray is crucial for ensuring safety and efficiency in any project. With a plethora of options available, selecting the most suitable tray tailored to your specific needs can be a daunting task. In this blog, we will explore the top five reasons why investing in the appropriate metal cable tray is essential for your installation.

From durability and versatility to compliance with safety standards, understanding these factors will empower you to make informed decisions that enhance the overall performance of your electrical systems. Whether you are involved in industrial, commercial, or residential applications, this guide will provide valuable insights to help you navigate the increasingly complex world of metal cable trays.

Join us as we delve into the essential elements that should guide your choice and ensure optimal cable management solutions.

From durability and versatility to compliance with safety standards, understanding these factors will empower you to make informed decisions that enhance the overall performance of your electrical systems. Whether you are involved in industrial, commercial, or residential applications, this guide will provide valuable insights to help you navigate the increasingly complex world of metal cable trays.

Join us as we delve into the essential elements that should guide your choice and ensure optimal cable management solutions.

Choosing the Right Metal Cable Tray: Understanding Material Durability and Load Capacity

When selecting a metal cable tray, understanding material durability and load capacity is crucial to ensure optimal performance in your specific environment. Different metals offer varying strengths and resistance to environmental factors like corrosion and humidity. For example, stainless steel is known for its exceptional strength and resistance to corrosive elements, making it ideal for industrial settings or locations prone to moisture. On the other hand, aluminum racks are lightweight and resistant to corrosion, making them a suitable choice for indoor applications where heavy loads are less of a concern.

Load capacity is another vital aspect to consider. Each cable tray design is engineered to support a certain weight, taking into account the thickness and type of metal used. It’s important to calculate the total weight of cables and electrical components that will be placed in the tray to avoid overload, which can lead to sagging or even failure of the tray. Additionally, ensure that the tray complies with industry standards and local regulations regarding load capacities to guarantee safety and functionality in your installation. By carefully assessing both the material durability and load capacity, you can make an informed decision that meets the demands of your specific application.

Comparing Different Metal Types: Aluminum vs. Steel for Cable Tray Applications

When it comes to selecting the right metal cable tray, the choice often narrows down to aluminum and steel due to their distinct attributes and applications. Aluminum trays stand out for their lightweight properties, making them easy to install and manipulate, especially in environments where weight restrictions are crucial. Additionally, aluminum's excellent resistance to corrosion makes it an ideal choice for outdoor installations or in facilities with high humidity. The natural non-magnetic property of aluminum also enhances its use in environments sensitive to electromagnetic interference.

On the other hand, steel cable trays offer remarkable strength and durability, making them suitable for heavy-duty applications. These trays are often preferred in industrial settings where they can endure high loads and mechanical stress. Steel can also be coated for additional corrosion resistance, providing a long-lasting solution in challenging environments. However, the heavier nature of steel can complicate installation in certain applications. Ultimately, the choice between aluminum and steel should consider factors like load requirements, environmental conditions, and ease of maintenance to ensure a proper fit for specific cable tray needs.

Industry Standards and Regulations Impacting Metal Cable Tray Selection

When selecting metal cable trays, understanding the industry standards and regulations that impact this selection is crucial. The U.S. cable tray market, valued at approximately USD 4.2 billion in 2023, is projected to grow at a CAGR of over 6.8% from 2024 to 2032, driven by increasing demand for reliable electrical distribution solutions. Factors like material choice—steel, aluminum, or stainless steel—play a significant role in compliance with standards set by organizations such as the National Electrical Code (NEC), Underwriters Laboratories (UL), and the International Electrotechnical Commission (IEC). These standards not only ensure safety but also dictate the performance capabilities of the trays in various environments.

Moreover, the importance of adhering to industry standards extends to fire safety considerations in cable management. High-quality cable trays that comply with UL and IEC standards mitigate risks associated with electrical fires in both commercial and utility installations. The evolution of regulations has heightened the focus on the durability and heat resistance of cable management systems. As the cable tray market anticipates growth, estimated to reach USD 9.5 billion by 2035 with a CAGR of around 4.36%, adhering to these standards will remain essential for manufacturers and end-users alike, ensuring safety and reliability in electrical systems.

Choosing the Right Metal Cable Tray for Your Specific Needs

Future Trends in Metal Cable Tray Design: Sustainability and Innovation

As industries become increasingly conscious of their environmental impact, the demand for sustainable metal cable trays is on the rise. Future trends in metal cable tray design are leaning towards innovative materials and production methods that prioritize sustainability. Manufacturers are exploring options like recycled metals and eco-friendly coatings to minimize their carbon footprint while providing durable, high-performance cable management solutions. These advancements not only serve environmental goals but also enhance the longevity and resilience of the products, making them more appealing to businesses looking for sustainable choices.

Furthermore, the integration of technology into metal cable tray designs is set to transform the market. Innovations such as modular designs, which allow for easy customization and installation, are gaining traction. This flexibility addresses specific needs across diverse applications, from telecommunications to data centers, where efficient cable management is crucial. As companies increasingly prioritize both functionality and sustainability, the evolution of metal cable trays is poised to align closely with these broader industry trends, paving the way for smarter, greener solutions in the years to come.

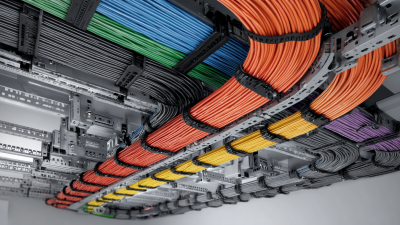

Maximizing Efficiency: The Role of Proper Cable Tray Configuration in Infrastructure

Efficient infrastructure management heavily relies on the proper configuration of metal cable trays, which play a crucial role in organizing electrical and data cables. According to a report by MarketsandMarkets, the global cable tray market is expected to grow from USD 3.9 billion in 2020 to USD 5.5 billion by 2025, emphasizing the increasing demand for effective cable management solutions in industrial applications. A well-designed cable tray system helps minimize the risk of cable damage and reduces maintenance costs, which in turn maximizes operational efficiency.

Proper cable tray configuration can dramatically impact installation time and long-term reliability. For instance, research from BSRIA indicates that an optimized cable management system can reduce installation times by up to 30%, allowing for faster project completion and reduced labor costs. Furthermore, correct cable segregation within trays can enhance airflow and cooling, significantly improving overall system performance. Consequently, organizations must prioritize selecting the right type of metal cable tray, factoring in their unique needs and the operational implications of their infrastructure to ensure maximum efficiency.

Related Posts

-

7 Essential Features of the Best Wire Raceway for Optimal Cable Management

-

Emerging Technologies Shaping Best Cable Tray Systems for 2025 and How to Optimize Your Setup

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

How to Select the Best Wire Mesh Cable Tray for Your Industrial Needs

-

Understanding Import and Export Certifications for the Best Stainless Steel Cable Tray

-

Unlocking Efficiency with Best Wire Basket Tray Advantages in Modern Warehousing