For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

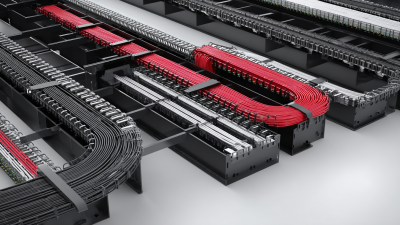

Ultimate Guide to Electrical Cable Trays: Optimizing Efficiency and Safety in Modern Installations

In today's fast-paced industrial environment, the efficiency and safety of electrical installations are paramount. The use of an electrical cable tray has emerged as a vital component in modern setups, providing a structured system for managing and protecting electrical wiring. This ultimate guide delves into the numerous advantages of utilizing cable trays, highlighting five key reasons why they are essential for optimizing both performance and safety.

From reducing installation time and costs to minimizing the risk of damage to cables, electrical cable trays play a crucial role in ensuring that electrical systems operate smoothly and without hazard. Join us as we explore the intricacies of electrical cable tray design and installation, and discover how they can dramatically enhance your electrical infrastructure.

From reducing installation time and costs to minimizing the risk of damage to cables, electrical cable trays play a crucial role in ensuring that electrical systems operate smoothly and without hazard. Join us as we explore the intricacies of electrical cable tray design and installation, and discover how they can dramatically enhance your electrical infrastructure.

Understanding the Different Types of Electrical Cable Trays in Modern Installations

In modern electrical installations, cable trays serve as vital systems for organizing and supporting cables efficiently and safely. Understanding the different types of electrical cable trays—such as ladder trays, perforated trays, and solid-bottom trays—can significantly enhance overall system performance. According to a report from Research and Markets, the global cable tray market is projected to reach USD 7.7 billion by 2026, demonstrating a growing recognition of the importance of optimized cable management in commercial and industrial applications.

Ladder trays are particularly popular due to their strength and ventilation capability, making them ideal for power distribution in data centers and manufacturing plants. On the other hand, perforated trays offer flexibility and ease of installation, making them suitable for low-voltage installations where heat dissipation is vital. Solid-bottom trays, while less common, provide extra protection for cables and are often used in environments where external damage or substances could compromise cable integrity. The choice of the right tray type can lead to increased safety and efficiency, ultimately contributing to better maintenance practices and reduced downtime in operations.

Key Factors Impacting the Choice of Cable Tray Material in Electrical Installations

When it comes to electrical installations, the choice of cable tray material is pivotal in ensuring both efficiency and safety. Various materials, such as steel, aluminum, and fiberglass, offer distinct advantages based on environmental conditions and load requirements. According to a report by the National Electrical Manufacturers Association (NEMA), steel trays are preferred for heavy-duty applications due to their strength and durability. However, they may not be ideal in corrosive environments where aluminum or fiberglass trays provide a better alternative.

Tips: Consider the specific applications when selecting the tray material. For environments with high humidity or exposure to chemicals, fiberglass trays can significantly reduce maintenance costs and improve long-term performance. On the other hand, aluminum trays are lightweight and offer excellent resistance to corrosion, making them suitable for both indoor and outdoor use.

Additionally, the choice of cable tray should align with the National Electrical Code (NEC) standards. A 2022 study by the International Wire and Cable Association (IWCA) indicated that adherence to these standards not only enhances safety but also optimizes energy efficiency, leading to a potential 10-15% reduction in operational costs. Assessing the local regulations and potential future needs can guide a more informed decision when selecting the appropriate cable tray material.

Analyzing Load-Bearing Capacity and Its Importance in Cable Tray Selection

When selecting an electrical cable tray, understanding load-bearing capacity is crucial to ensuring safety and functionality in modern installations. The load-bearing capacity determines how much weight the cable tray can support without compromising its structural integrity. This factor is influenced by materials, design, and dimensions of the tray. Choosing a tray that meets or exceeds the expected load will prevent future issues, such as sagging or damage to the cables.

Tip: Always consult with manufacturers’ specifications and load charts to make informed decisions about cable tray selection. Consider future expansion needs, as underestimating load requirements can lead to costly modifications down the road.

Additionally, it’s essential to consider the installation environment. Factors such as temperature fluctuations, humidity, and exposure to corrosive elements can affect the load-bearing capacity of a cable tray. Selecting materials that can withstand environmental challenges will extend the lifespan of the installation.

Tip: Conduct a thorough site assessment before installation to anticipate potential environmental impacts. This proactive approach will not only optimize the cable tray's performance but also enhance the overall safety of the electrical system.

Best Practices for Safety Compliance in Electrical Cable Tray Installations

When it comes to electrical cable tray installations, safety compliance should always be a top priority. Proper installation not only enhances the efficiency of electrical systems but also minimizes risks associated with cable management. One key practice is ensuring that all trays are securely mounted and are capable of supporting the weight of the cables they will carry. Regular inspections can identify any signs of wear or misalignment that could lead to accidents or failures.

**Tip 1:** Always adhere to local codes and standards when planning and installing cable trays. These regulations are designed to protect both people and property, so staying informed will help ensure compliance.

Another critical aspect of safety is providing adequate clearance around cable trays to allow for airflow and maintenance access. Overcrowding can lead to overheating, which poses a significant fire risk. Implementing proper cable separation techniques can also prevent electromagnetic interference, improving overall system performance.

**Tip 2:** Consider using fire-resistant materials and incorporating protective barriers when designing cable tray systems. This practice not only complies with safety standards but also enhances the durability and longevity of your installations.

Ultimate Guide to Electrical Cable Trays: Optimizing Efficiency and Safety in Modern Installations

| Dimension | Description | Best Practices | Safety Compliance |

|---|---|---|---|

| Material | Common materials include steel, aluminum, and fiberglass. | Choose the right material based on environmental conditions. | Ensure materials meet relevant safety standards. |

| Load Capacity | Cables’ weight and spacing determine load capacity. | Calculate load requirements accurately. | Adhere to the maximum load limits specified by regulations. |

| Installation Height | Optimal heights minimize risks and facilitate maintenance. | Install trays at safe, accessible heights. | Follow local codes on installation heights. |

| Ventilation | Proper ventilation prevents overheating of cables. | Ensure adequate airflow around trays. | Comply with standards for temperature control. |

| Accessibility | Easy access is crucial for maintenance and inspections. | Design layouts that allow easy access to trays. | Ensure paths to trays are clear and safe. |

Innovative Design Trends in Cable Tray Systems for Enhanced Efficiency

In today's fast-paced electrical installations, the design of cable tray systems has evolved significantly to enhance efficiency and ensure safety. One of the most innovative trends is the adoption of modular cable trays, allowing for flexible configurations that can easily adapt to changing project requirements.

These modular systems not only streamline the installation process but also reduce material waste, making them an environmentally friendly option. The ease of installation encourages electricians to make smarter design choices, ultimately improving workflow and productivity on the job site.

These modular systems not only streamline the installation process but also reduce material waste, making them an environmentally friendly option. The ease of installation encourages electricians to make smarter design choices, ultimately improving workflow and productivity on the job site.

Another emerging trend is the use of advanced materials, such as lightweight composites and corrosion-resistant alloys. These materials contribute to the longevity and durability of cable tray systems, reducing maintenance needs over time. Enhanced ventilation designs in cable trays are also gaining popularity, which help in managing heat dissipation, leading to improved performance and safety for electrical components housed within the trays. By focusing on innovative design principles, modern cable tray systems are poised to meet the demands of contemporary electrical installations while optimizing efficiency and safety.

Related Posts

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

Ultimate Guide to Choosing the Best Wire Management Tray: Optimize Efficiency with Industry Insights

-

Emerging Technologies Shaping Best Cable Tray Systems for 2025 and How to Optimize Your Setup

-

Understanding Import and Export Certifications for the Best Stainless Steel Cable Tray

-

7 Essential Tips for Choosing the Right Cable Tray Systems for Your Project