For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

7 Essential Tips for Choosing the Right Cable Tray Cover to Enhance Safety and Efficiency

In today's fast-paced industrial environment, the selection of an appropriate cable tray cover is critical for both safety and operational efficiency. According to a report by the National Electrical Manufacturers Association (NEMA), improper cable management can lead to increased maintenance costs and safety hazards, with cable-related incidents accounting for approximately 15% of workplace accidents. Additionally, the global market for cable management systems is projected to grow at a CAGR of 8.5% from 2021 to 2028, indicating a heightened focus on enhanced safety measures within electrical installations. As industries increasingly prioritize compliance with safety regulations and operational efficiency, understanding the nuances of selecting the right cable tray cover becomes essential. This guide aims to provide seven essential tips to help you make informed choices that not only enhance safety but also streamline cable management practices in your facility.

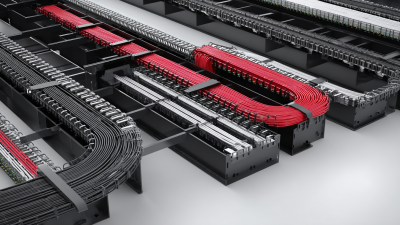

Understanding the Importance of Cable Tray Covers in Safety Measures

Cable tray covers play a crucial role in maintaining safety measures within industrial and commercial settings. By covering exposed electrical wires and cables, these covers help prevent accidental contact, which can lead to severe electrical shocks or fires. Moreover, they protect cables from environmental factors such as dust, moisture, and harmful chemicals, ensuring that the integrity of the wiring system is preserved over time. This level of protection is essential not only for the safety of workers but also for the overall reliability of electrical systems.

In addition to safety, the use of cable tray covers enhances operational efficiency. When cables are properly covered, it becomes easier to manage and organize them, reducing the risk of tangles and ensuring quick access for maintenance or upgrades. This organized approach not only streamlines work processes but also minimizes downtime, allowing for smoother operation within a facility. Therefore, choosing the right cable tray cover is integral to fostering a safe and efficient work environment.

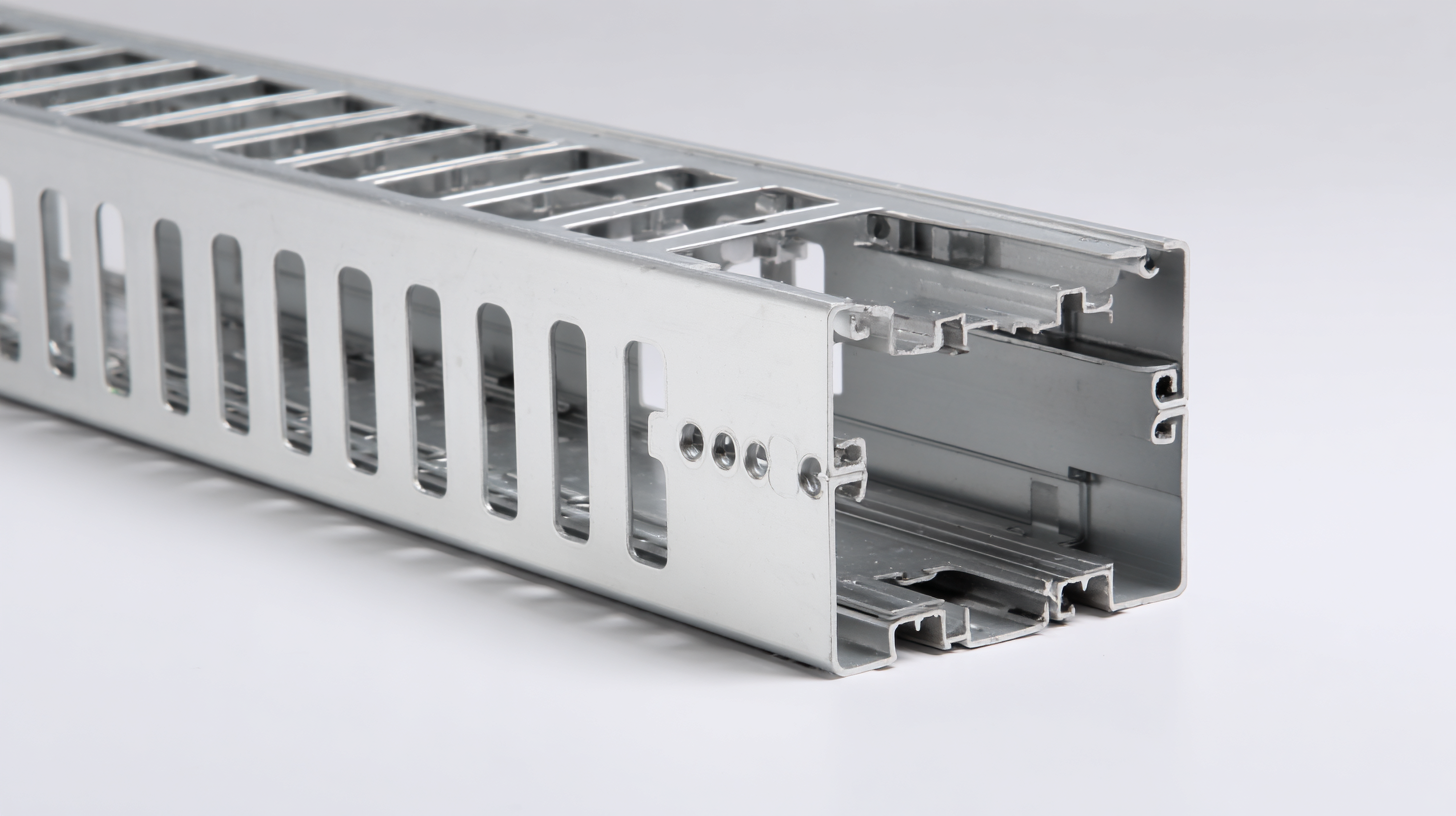

Types of Materials to Consider for Optimal Cable Tray Cover Performance

When selecting the right cable tray cover, considering the materials used is crucial for optimizing both safety and efficiency. Common materials include metal, plastic, and composite options, each offering unique advantages based on the specific application environment. For instance, metal covers, such as those made from stainless steel or aluminum, provide robust durability and are ideal for industrial settings where harsh conditions or heavy loads are present. They are particularly effective in environments that require fire resistance and enhanced mechanical strength.

On the other hand, plastic and composite materials offer excellent flexibility and corrosion resistance. PVC and polycarbonate covers are lightweight, making them easier to handle and install, while also being resistant to chemicals and moisture. These materials are often favored in commercial or residential applications where weight reduction and lower maintenance are critical. Ultimately, selecting the right material for cable tray covers is essential in ensuring they perform optimally under varying environmental conditions, contributing to improved safety and operational efficiency.

Evaluating Load Capacity and Environmental Conditions for Your Cable Tray

When selecting a cable tray cover, understanding load capacity and environmental conditions is critical to ensuring both safety and efficiency. According to a report from the National Electrical Manufacturers Association (NEMA), cable trays can support significant loads, with designs available to handle capacities ranging from 200 pounds per square foot to over 1,000 pounds per square foot, depending on the material and construction. These specifications must be thoroughly evaluated to match the demands of your specific installation, ensuring that the chosen cover can withstand the anticipated weight without compromising structural integrity.

In addition to load capacity, the environmental conditions where the cable tray will be installed play a vital role. A study published by the Institute of Electrical and Electronics Engineers (IEEE) notes that factors like temperature, humidity, and exposure to corrosive substances can dramatically affect the lifespan of cable trays and their covers. For instance, in outdoor environments where UV exposure is a concern, selecting UV-resistant materials can extend the service life of the cover. By thoroughly assessing these factors and choosing accordingly, organizations can enhance safety and optimize operational efficiency within their facilities.

7 Essential Tips for Choosing the Right Cable Tray Cover to Enhance Safety and Efficiency

| Dimension | Optimal Value | Considerations |

|---|---|---|

| Load Capacity (lbs) | 150 - 300 | Ensure it meets the installation requirements |

| Environmental Rating | IP20 - IP68 | Assess exposure to moisture and particles |

| Material Type | Steel/Aluminum | Choose based on corrosion resistance needs |

| Temperature Rating (°F) | -40 to 140 | Evaluate ambient temperature conditions |

| Installation Method | Surface Mounted/Hung | Determine feasibility based on site conditions |

| Tray Width (inches) | 6 - 12 | Consider cable volume and type |

| Cover Type | Perforated/Solid | Choose based on heat dissipation and aesthetics |

Key Features to Look for in Cable Tray Covers to Enhance Efficiency

When selecting cable tray covers, several key features should be prioritized to maximize both safety and operational efficiency. First and foremost, materials matter; look for covers made from durable and resistant substances, such as fiberglass or metal, which can withstand environmental stresses and prevent damage to cables. Additionally, consider the design of the cover; vented options allow for better airflow and heat dissipation, crucial for preventing overheating of electrical lines.

Another tip is to assess the ease of installation and maintenance. Covers that are lightweight and come with user-friendly fasteners can significantly reduce downtime and labor costs during installation. Moreover, ensuring that the cable tray cover has appropriate securing mechanisms will enhance safety by protecting against accidental dislodgement or movement.

Lastly, ensure that the cable tray covers comply with safety regulations and standards relevant to your industry. This not only enhances safety but also promotes efficiency by minimizing the risk of accidents. By focusing on these essential features, businesses can create safer and more effective electrical environments that support their operational goals.

Safety and Efficiency in Cable Tray Covers

This chart illustrates the key features to consider when selecting cable tray covers, highlighting their impact on safety and efficiency.

Tips for Proper Installation and Maintenance of Cable Tray Covers

When it comes to the installation and maintenance of cable tray covers, proper procedures are essential to ensure both safety and efficiency. One crucial tip is to regularly inspect cable tray covers for any signs of wear and damage. This includes checking for cracks, corrosion, or any debris that may have accumulated over time. Addressing these issues promptly can prevent larger problems and maintain the integrity of the cables within the tray.

Another important aspect is ensuring that the installation is performed according to the manufacturer's guidelines. This involves using the appropriate tools and hardware, and adhering to recommended practices, such as securing covers to minimize movement and reduce the risk of accidents. Additionally, employing proper sealing techniques can enhance protection against water and dust infiltration, further extending the lifespan of the cable trays.

Lastly, it's beneficial to establish a maintenance schedule that includes cleaning the cable tray covers regularly. Keeping them free from dirt and residues will not only improve their appearance but also ensure optimal performance. By following these tips, you can enhance safety and efficiency in your cable management systems.

Related Posts

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Ultimate Guide to Choosing the Best Wire Management Tray: Optimize Efficiency with Industry Insights

-

7 Essential Tips for Choosing the Right Cable Tray Systems for Your Project

-

Ultimate Guide to Electrical Cable Trays: Optimizing Efficiency and Safety in Modern Installations

-

Emerging Technologies Shaping Best Cable Tray Systems for 2025 and How to Optimize Your Setup

-

Understanding Import and Export Certifications for the Best Stainless Steel Cable Tray