For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

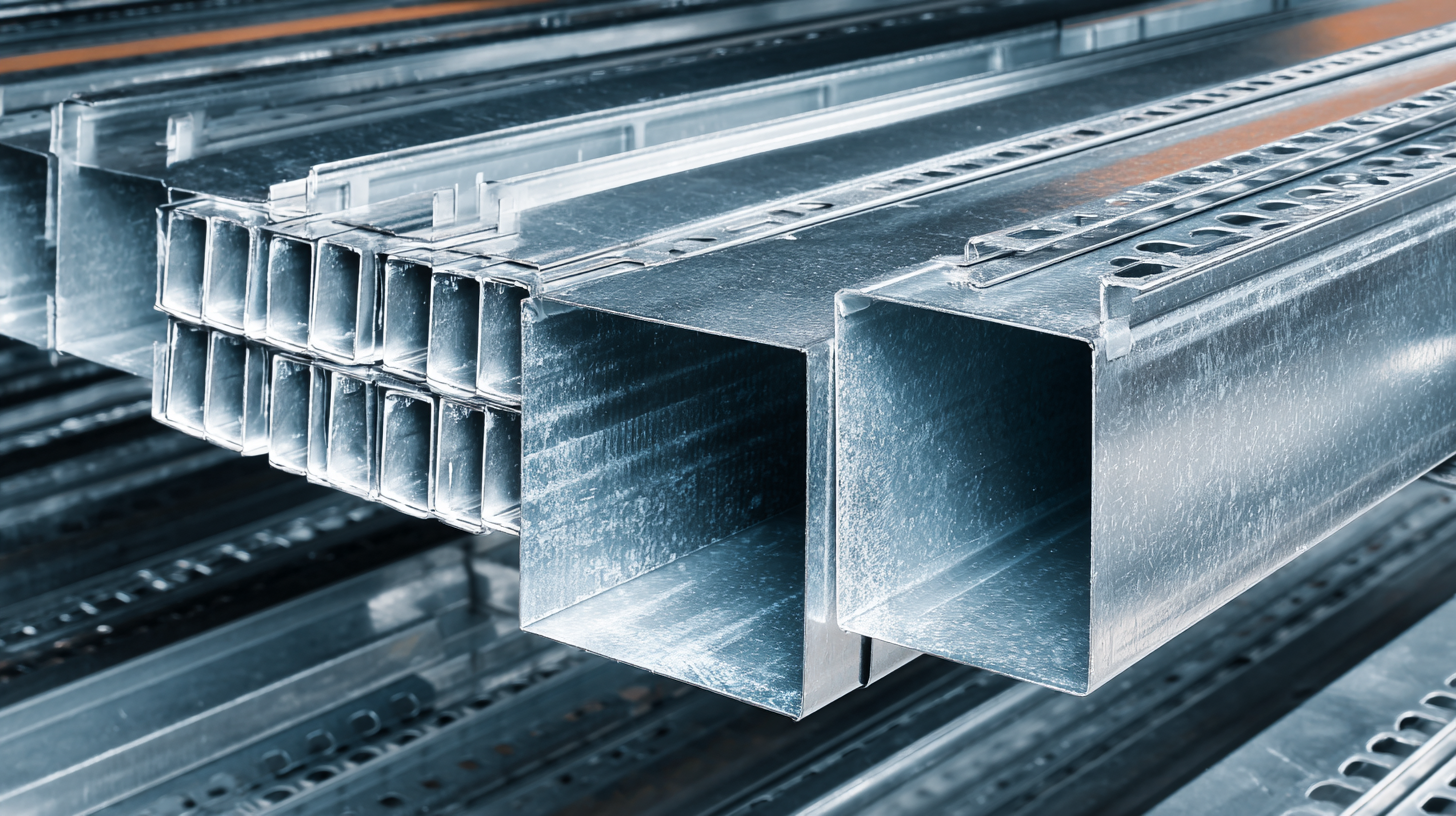

Understanding Import and Export Certifications for the Best Stainless Steel Cable Tray

The growing demand for stainless steel cable trays in various industrial applications highlights the need for a comprehensive understanding of import and export certifications. According to a report from Market Research Future, the global cable tray market is projected to reach approximately $4.5 billion by 2025, with a significant portion attributed to stainless steel options due to their durability, corrosion resistance, and aesthetic appeal.

As businesses seek to comply with international standards and regulations, knowledge of certifications such as ISO and CE becomes crucial for manufacturers and distributors alike. This blog will guide you through the essential aspects of import and export certifications for stainless steel cable trays, ensuring that you are well-informed to navigate the complexities of global trade in this increasingly competitive market.

The growing demand for stainless steel cable trays in various industrial applications highlights the need for a comprehensive understanding of import and export certifications. According to a report from Market Research Future, the global cable tray market is projected to reach approximately $4.5 billion by 2025, with a significant portion attributed to stainless steel options due to their durability, corrosion resistance, and aesthetic appeal.

As businesses seek to comply with international standards and regulations, knowledge of certifications such as ISO and CE becomes crucial for manufacturers and distributors alike. This blog will guide you through the essential aspects of import and export certifications for stainless steel cable trays, ensuring that you are well-informed to navigate the complexities of global trade in this increasingly competitive market.

The Importance of Import and Export Certifications for Stainless Steel Cable Trays

When it comes to stainless steel cable trays, navigating the realm of import and export certifications is crucial for ensuring product quality and compliance. These certifications serve as a guarantee that the cable trays meet specific industry standards and regulations. For manufacturers and suppliers, having the appropriate certifications not only enhances credibility but also assures customers that they are investing in reliable and durable products.

Import and export certifications also play a vital role in global trade. They facilitate smoother transactions between countries by ensuring that products meet the necessary safety, environmental, and material composition regulations. For buyers, this means peace of mind knowing that the stainless steel cable trays they are acquiring have been vetted for quality and safety, thereby reducing the risk of substandard products entering the market. Understanding and prioritizing these certifications is essential for stakeholders in the cable tray industry, as it directly impacts marketability and compliance.

Key Certifications Needed for High-Quality Stainless Steel Cable Trays

When selecting high-quality stainless steel cable trays, understanding the requisite certifications is essential for ensuring safety, durability, and performance. Among the key certifications to consider are UL (Underwriters Laboratories) and ISO (International Organization for Standardization), which assess the product's structural integrity and compliance with international standards. According to industry reports, products that meet these certifications demonstrate a failure rate of less than 1% in critical applications, highlighting their reliability in supporting electrical systems.

Furthermore, the growing demand for sustainable and efficient electrical management systems, particularly in sectors like rooftop solar installations, underscores the importance of these certifications. As outlined in the latest Rooftop Solar BOS Buyer’s Guide, high-quality mounting systems and cable management solutions are vital to optimizing the performance of solar PV systems. Investing in certified stainless steel cable trays not only enhances the system's safety but can also significantly reduce maintenance costs over the product's lifetime, making them a smart choice for modern electrical installations.

How to Ensure Compliance with International Import/Export Standards

When dealing with stainless steel cable trays, understanding import and export certifications is crucial to ensure adherence to international standards. Compliance with these regulations not only guarantees the quality and safety of the product but also facilitates smoother trade processes. Different countries have varying requirements regarding certifications, such as ISO standards or specific national regulations, which can impact the ability to enter certain markets. Therefore, businesses must familiarize themselves with the regulatory framework of both the importing and exporting nations.

To ensure compliance, companies should conduct thorough research on certification bodies relevant to their target regions. This might include obtaining certifications from recognized organizations that validate the quality and safety of the stainless steel cable trays. Engaging with suppliers who already meet international standards can also expedite the certification process. Additionally, maintaining accurate documentation and clear communication with customs authorities can help prevent delays or penalties during import or export activities. By prioritizing compliance with international import/export standards, businesses can enhance their global competitiveness and foster customer trust.

The Impact of Certifications on the Durability and Performance of Cable Trays

When it comes to stainless steel cable trays, certifications play a crucial role in determining their durability and performance. Industry standards such as UL, CE, and ISO certifications not only signify adherence to safety and quality protocols, but also directly impact the lifespan of these trays. According to a report by the International Association of Electrical Inspectors, certified stainless steel cable trays can last up to 30% longer under harsh environmental conditions compared to non-certified counterparts. This longevity is largely due to rigorous testing procedures that evaluate corrosion resistance and load-bearing capabilities.

Additionally, certifications reflect a manufacturer's commitment to quality materials and engineering practices. A study by the National Electrical Manufacturers Association indicates that certified products often involve higher-quality stainless steel grades, which can withstand environmental stresses more effectively. For instance, the use of 304 or 316 stainless steel, which is frequently verified through certification processes, can reduce the risk of failure in demanding applications, thereby ensuring safe and reliable cable management systems in both commercial and industrial settings.

Navigating the Certification Process: Best Practices for Manufacturers and Suppliers

When it comes to manufacturing and supplying stainless steel cable trays, navigating the certification process can seem daunting. However, understanding the key certifications required can significantly streamline operations. Manufacturers should prioritize compliance with international standards such as ISO and ASTM, which not only enhance product reliability but also demonstrate commitment to quality. Ensuring that your products meet these standards is essential for market acceptance and reducing potential liability issues.

**Tip:** Maintain thorough documentation throughout the production process. This includes test reports and quality assurance procedures, which can greatly assist when applying for certifications.

Another crucial aspect is choosing the right certification bodies. Collaborating with accredited organizations ensures that the certification process aligns with global requirements. Manufacturers and suppliers should regularly update their knowledge of certification changes and standards in the industry.

**Tip:** Establish a relationship with a certification consultant who can provide guidance and support for specific requirements related to your product line. This proactive approach can save time and resources in the long run.