For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

Top Strategies for Maximizing Efficiency with Wire Trays in Your Facility

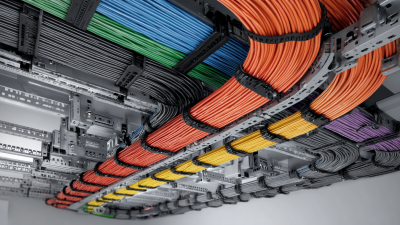

In today's fast-paced industrial landscape, maximizing efficiency is paramount, and one of the most effective ways to achieve this is through the strategic use of wire trays. According to a report from the Electrical Contractor magazine, facilities that optimize their cable management solutions, including the utilization of wire trays, can see a reduction in installation time by as much as 30%. Additionally, a study by the National Electrical Manufacturers Association (NEMA) highlights that an organized cable management system not only enhances safety but also improves overall operational efficiency by minimizing downtime during maintenance. As businesses strive to streamline processes and enhance productivity, understanding the best strategies for implementing wire trays becomes essential for maintaining a competitive edge in the market.

Understanding the Common Issues Associated with Wire Trays

When it comes to wire trays, understanding the common issues associated with their use is crucial for maintaining efficiency and safety in your facility. One significant issue arises in solar installations, where improper wire management is often viewed as an optional expense rather than a critical component. This oversight can lead to detrimental consequences, such as damaged wire insulation, which may result in ground faults, system downtime, and even fire hazards. Facilities must prioritize comprehensive wire management strategies to ensure the longevity and reliability of their electrical systems.

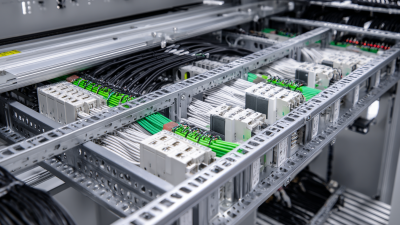

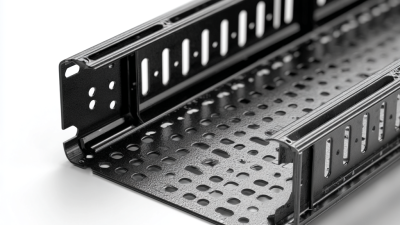

Additionally, it’s essential to consider the various types of wire trays available, including ladder-type, perforated-type, and solid-bottom trays. Each of these designs has unique strengths and weaknesses that can influence the performance and safety of the entire system. For instance, ladder-type trays provide excellent ventilation and facilitate easy maintenance, while solid-bottom trays may offer better protection for sensitive wiring. By understanding these characteristics and proactively addressing common wire management pitfalls, facility managers can significantly enhance operational efficiency and safety.

Top Strategies for Maximizing Efficiency with Wire Trays in Your Facility - Understanding the Common Issues Associated with Wire Trays

| Common Issues | Potential Solutions | Impact on Efficiency | Recommended Best Practices |

|---|---|---|---|

| Overloading Wire Trays | Regular weight assessments and compliance checks | Reduces the risk of damage and maintenance needs | Train staff on load limits |

| Poor Cable Management | Implement cable ties and labels | Enhances organization and accessibility | Schedule regular maintenance reviews |

| Insufficient Ventilation | Ensure adequate airflow around trays | Prevents overheating and equipment failure | Monitor temperature levels in work areas |

| Corrosion and Material Wear | Use corrosion-resistant materials | Increases lifespan of wire trays | Conduct regular inspections for wear |

| Difficult Access for Maintenance | Reorganize layout for better accessibility | Improves maintenance turnaround time | Plan systematic layout reviews |

Evaluating the Impact of Wire Tray Design on Efficiency

When considering the efficiency of facilities that utilize wire trays, the design of these trays plays a critical role. The global FRP cable tray market, valued at approximately $253.48 million in 2019, is projected to significantly expand to about $696.78 million by 2032, indicating a robust CAGR of 8.36% during this forecast period. This growth underscores the increasing recognition of effective wire tray designs in boosting operational efficiency and safety in facilities across various sectors.

One key tip for maximizing efficiency with wire trays is to optimize the layout to minimize cable lengths while ensuring adequate airflow and accessibility for maintenance. Consider using trays that are designed with features such as ventilation slots or a modular structure, which can enhance the cooling of cables—crucial in environments with high equipment density. Another aspect to evaluate is the material composition of the trays; using durable and lightweight materials can reduce installation time and improve overall system resilience.

Additionally, integrating wire trays with smart monitoring systems can provide real-time data about temperature and load, allowing for proactive measures to prevent overheating and maintain efficiency. These considerations align well with the growing trend of sustainable technology in industries, emphasizing not only increased productivity but also energy efficiency.

Solutions for Minimizing Wire Tray Maintenance Challenges

Wire trays are essential components in modern facilities, providing structured management for wiring and cabling. However, maintenance challenges can lead to inefficiencies and increased operational costs. According to a 2022 report by the Electrical Safety Foundation International (ESFI), improper installation and inadequate maintenance of wire trays can increase equipment failure rates by up to 30%, resulting in significant downtime and repair expenses.

To minimize these challenges, organizations should adopt a proactive maintenance strategy. Regular inspections every six months can help identify wear and tear before they escalate into larger issues. A study published in the Journal of Facility Management (2023) suggests that facilities implementing routine maintenance protocols saw a 25% reduction in wiring-related incidents. Utilizing high-quality materials and investing in innovative designs, such as modular wire tray systems, can also enhance durability and performance. By prioritizing these strategies, organizations can effectively mitigate maintenance challenges associated with wire trays, ensuring a more efficient and reliable facility.

Best Practices for Wire Tray Installation to Avoid Problems

When it comes to wire tray installation, adhering to best practices is crucial to ensure safety and efficiency in your facility. One of the first steps is to conduct a thorough site assessment. This involves evaluating factors such as load capacity, the weight of cables, and environmental conditions. Understanding these elements will aid in selecting the appropriate type and size of wire trays necessary to accommodate your specific needs.

Additionally, maintaining adequate spacing and organization of cables within the trays can significantly reduce wear and tear, ultimately extending the lifespan of the electrical systems.

Proper installation techniques also play a critical role in avoiding potential issues down the line. It’s essential to follow manufacturer guidelines for mounting heights and installation angles, as these specifications are designed to optimize performance. Utilizing corrosion-resistant materials, especially in environments prone to moisture or chemical exposure, can further protect against degradation.

Finally, regular inspections are necessary to identify signs of overcrowding or physical damage, ensuring that any problems are addressed promptly to maintain operational efficiency.

Innovative Modifications to Enhance Wire Tray Performance

Innovative modifications to wire trays can significantly enhance their performance and boost efficiency in various facilities. Recent studies indicate that optimizing design elements—much like the advancements being made in solar distillation—can lead to improved operational capabilities. For instance, enhancing the structural integrity and material selection in wire trays can lead to better load distribution and increased durability. According to industry reports, facilities that have incorporated high-strength materials in their wire tray systems have seen a reduction in maintenance costs by up to 30%, demonstrating the tangible benefits of innovative design choices.

Furthermore, integrating features such as thermal insulation and modular designs can enhance the overall functionality of wire trays. Similar to the integration of heaters and baffles in solar distillation systems that improves evaporation rates, applying similar principles to wire tray design can improve airflow management and heat dissipation. A comparative analysis shows that facilities implementing these modifications can achieve up to 20% more efficiency in their operational processes. In today's competitive landscape, such enhancements are not just advantageous; they are essential for maintaining operational excellence.

Maximizing Efficiency with Wire Trays in Your Facility

This chart illustrates the impact of various modifications on wire tray performance, showcasing efficiency improvements across different strategies.

Related Posts

-

Innovative Solutions for Cable Management Issues in Power Plant Applications Using Best Wire Tray

-

China Leads the Global Market with Best Cable Tray Covers for Unmatched Quality

-

7 Essential Features of the Best Wire Raceway for Optimal Cable Management

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Innovations in Wire Mesh Cable Trays Shaping the Future of Infrastructure by 2025

-

Ultimate Guide to Choosing the Best Wire Management Tray: Optimize Efficiency with Industry Insights