For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

How to Optimize Your Cable Ladder Installation for Maximum Efficiency

In today’s fast-paced industrial landscape, optimizing your cable ladder installation is crucial for achieving maximum efficiency in electrical distribution systems. Cable ladders are key components that support and organize various cables, ensuring safety and accessibility for maintenance and upgrades. However, the effectiveness of a cable ladder setup extends beyond just installation; it encompasses strategic planning, proper materials selection, and adherence to best practices. This blog will delve into the essential strategies for optimizing cable ladder installation, highlighting the best types of cable ladders suited for various applications. By implementing these insights, businesses can enhance operational efficiency, reduce downtime, and ultimately achieve superior performance in their electrical management systems. Let’s explore how to make the most out of your cable ladder installation.

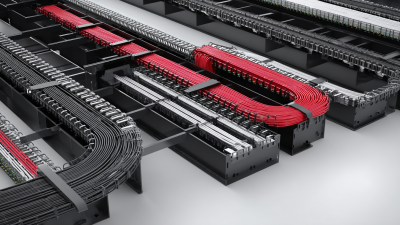

Understanding Cable Ladder Types and Their Applications for Efficient Installation

When it comes to optimizing your cable ladder installation, understanding the different types of cable ladders and their applications is crucial. Cable ladders are essential for organizing and supporting electrical cables in various environments. Three common types include perforated cable ladders, which offer ventilation and are ideal for environments with high heat; trough cable ladders, which provide extra protection for critical cables; and rung cable ladders, which allow easy access for maintenance and modifications.

When selecting the right cable ladder, consider the specific needs of your installation. For outdoor applications, choose galvanized steel or aluminum options for their durability against the elements. Meanwhile, for indoor settings where aesthetics matter, powder-coated ladders can blend seamlessly into your infrastructure.

Additionally, ensure proper spacing between supports to minimize sagging and enhance load distribution. Remember to maintain adequate clearance for thermal expansion and accessibility for routine inspections. By tailoring your approach to the type of cable ladders used and following these tips, you can significantly boost the efficiency of your installation, ensuring a long-lasting and effective solution.

Key Factors Influencing Cable Ladder Load-Bearing Capacity in Installations

When optimizing cable ladder installations, understanding the key factors influencing

load-bearing capacity

is crucial for ensuring maximum efficiency and safety. According to the National Electrical Manufacturers Association (NEMA),

the load-bearing capacity of cable ladders is primarily determined by materials, dimensions, and spacing.

For instance, using galvanized steel for ladder construction can enhance durability

and support higher loads, with typical designs capable of bearing up to

2000 lbs per span when properly installed.

Another significant factor is the spacing and support configuration of the cable ladders.

The American National Standards Institute (ANSI) recommends setting supports no more than

10 feet apart to prevent sagging and ensure stability under maximum load conditions.

Additionally, incorporating proper cross-bracing can improve rigidity, allowing ladders to support larger quantities of cables

without compromising integrity. In real-world applications, companies that adhere to these guidelines report a

reduction in cable maintenance costs by up to 30%,

emphasizing the financial and operational benefits of optimizing installation practices.

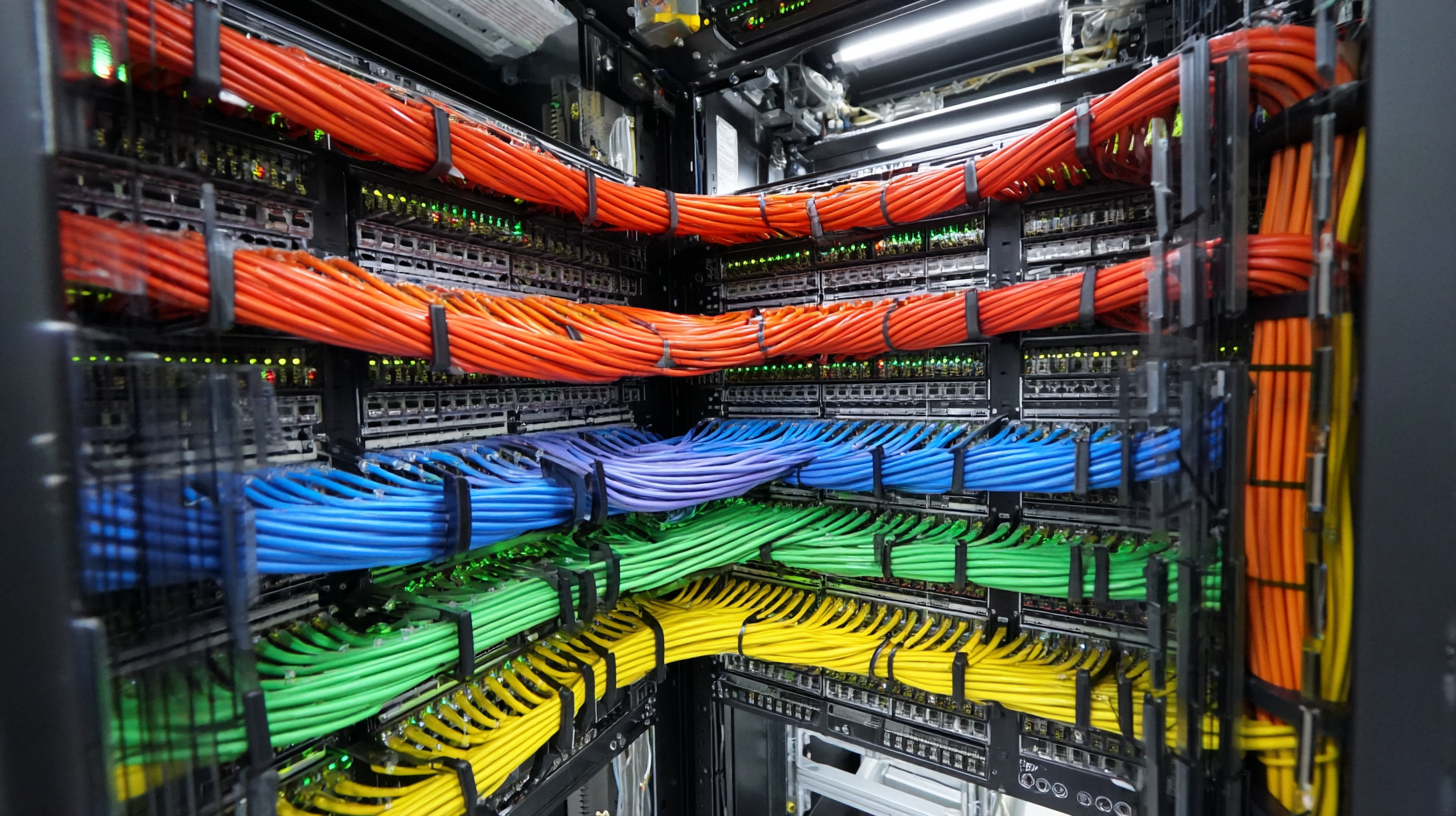

Best Practices for Cable Ladder Layout to Enhance Airflow and Accessibility

When planning your cable ladder installation, the layout is crucial for optimizing airflow and ensuring easy accessibility. It’s essential to consider the spacing and arrangement of cables, as this can significantly impact the performance and longevity of the entire system. Properly managing the placement of ladders will not only improve air circulation, reducing overheating risks, but will also facilitate maintenance tasks, allowing technicians to quickly and efficiently access the cables when needed.

To enhance your layout, start by grouping cables of similar function and purpose together. This practice minimizes unnecessary tangling and promotes better organization. Additionally, incorporating adjustable cable supports can help manage airflow while providing flexibility for future expansions. Remember that a well-thought-out cable ladder setup can save your team time and effort during maintenance, leading to a more efficient operation and ultimately extending the lifecycle of your equipment. Emphasizing these best practices in your installation process will result in a setup that maximizes performance and accessibility.

Common Mistakes to Avoid When Installing Cable Ladders for Optimal Performance

When installing cable ladders, avoiding common mistakes can dramatically improve efficiency and performance. One of the most frequent errors is improper spacing between supports. Failing to adhere to recommended distances can lead to sagging, which may cause cables to wear prematurely or become entangled. It’s crucial to consult the manufacturer’s guidelines and industry standards to ensure that supports are placed at the optimal intervals for your specific installation.

Another common mistake is neglecting to consider the weight of the cables being installed. Overloading a cable ladder can result in structural failure, compromising not only the cables but also the overall safety of the installation. It's essential to accurately assess the weight specifications and plan for future cable additions to ensure that the ladder can handle the load. Additionally, using the wrong type of ladder for the specific environment—be it outdoor exposure or corrosive conditions—can lead to early deterioration and inefficient performance. By addressing these common pitfalls, you can enhance the longevity and functionality of your cable ladder installations.

How to Optimize Your Cable Ladder Installation for Maximum Efficiency

| Dimension | Recommendation | Common Mistakes |

|---|---|---|

| Installation Angle | Ensure a 30-degree angle for optimal cable support. | Installing too steeply can cause cable stress. |

| Spacing Between Rungs | Keep rung spacing at least 12 inches apart. | Too close spacing can lead to cable damage. |

| Load Capacity | Verify ladder load ratings before installation. | Exceeding weight limits can compromise safety. |

| Securing Method | Use appropriate brackets for secure installation. | Inadequate securing can lead to instability. |

| Cable Management | Utilize cable ties for organization and safety. | Neglecting organization can cause tangling and damage. |

Utilizing Industry Standards to Improve Safety and Compliance in Cable Ladder Installations

When planning a cable ladder installation, adherence to industry standards is paramount for enhancing safety and ensuring compliance. These standards provide essential guidelines that help prevent accidents and ensure the integrity of the installation. For instance, following the National Electric Code (NEC) regulations helps in selecting the correct materials and dimensions for cable ladders, ultimately contributing to a safer working environment. Proper installation techniques, such as secure anchoring and appropriate spacing between rungs, further align with these standards, reducing the risk of cable management failures over time.

Moreover, utilizing industry standards not only safeguards operators but also promotes operational efficiency. By ensuring that installations adhere to recognized practices, companies can minimize downtime related to maintenance and adjustments. Regular inspections based on these standards can reveal potential hazards or maintenance needs before they escalate into costly issues. Thus, prioritizing compliance not only fosters a culture of safety but also streamlines operations, making the cable ladder installation a critical component in any infrastructure project.

Cable Ladder Installation Efficiency Analysis

Related Posts

-

Ultimate Checklist for Choosing the Best Metal Cable Tray for Your Project Needs

-

Mastering the Best Cable Tray Desk for Ultimate Workspace Organization

-

Emerging Technologies Shaping Best Cable Tray Systems for 2025 and How to Optimize Your Setup

-

7 Essential Tips for Choosing the Right Cable Tray Systems for Your Project

-

The Future of Ladder Cable Tray Innovation in Electrical Infrastructure

-

Innovations in Wire Mesh Cable Trays Shaping the Future of Infrastructure by 2025