For over 50 years, we have dedicated ourselves to providing Industry with best in class wire management solutions and to helping solve mission critical issues.

The needs of today’s schools and universities are changing fast. When it comes to anticipating and meeting those needs, MonoSystems is in a class of its own.

For the past five decades, we’ve made it our business to offer more value to our partners, which in turn provides greater value to their customers.

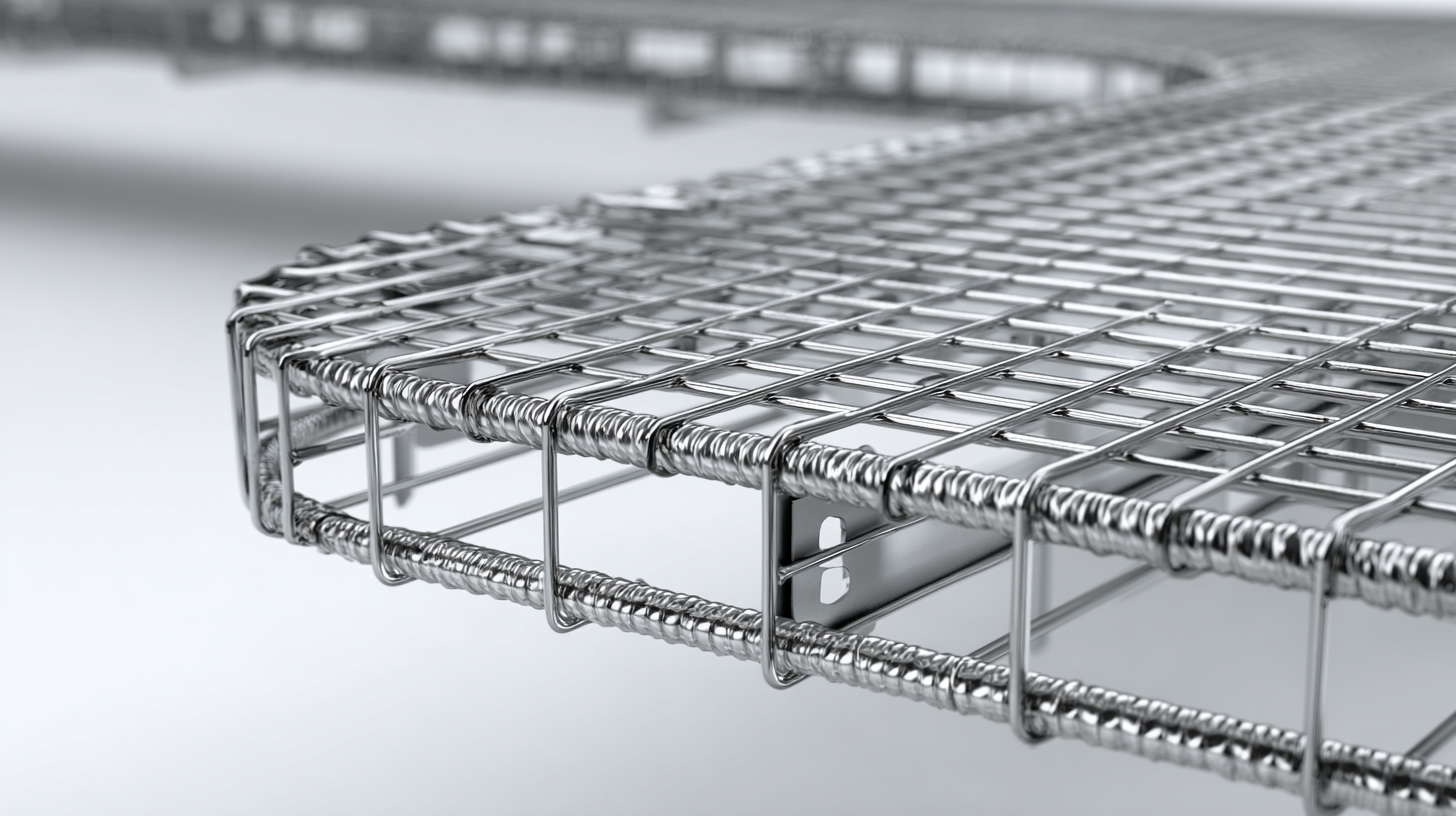

How to Select the Best Wire Mesh Cable Tray for Your Industrial Needs

In today's industrial landscape, the demand for efficient cable management solutions has surged, with the global wire mesh cable tray market projected to reach $2.1 billion by 2026, growing at a CAGR of 6.5% from 2021. This growth is largely driven by the expanding infrastructure, increased reliance on electricity, and the need for safety compliance in various sectors. As industries prioritize noise reduction, weight optimization, and cost-effectiveness, selecting the appropriate wire mesh cable tray becomes crucial. However, the process involves numerous considerations, such as material quality, design flexibility, and the reputation of suppliers. Understanding how to identify reputable vendors who offer high-quality products is essential for ensuring longevity and efficiency in industrial applications. This blog will explore key factors to consider when sourcing wire mesh cable trays and how to find top-tier suppliers that meet your specific requirements.

Types of Wire Mesh Cable Trays and Their Industrial Applications

When selecting a wire mesh cable tray for industrial applications, understanding the different types available can facilitate the best choice for your specific needs. Wire mesh cable trays, often made from galvanized steel or stainless steel, are versatile and offer optimal airflow and heat dissipation, making them perfect for environments where thermal management is critical. For instance, open mesh trays are ideal for bundling multiple cable types, enhancing both safety and organization in areas with heavy wire usage.

Another popular type is the ladder-style wire mesh tray. This design provides sturdy support while allowing for easy installation and maintenance of cables. Ladder trays are particularly beneficial in locations where large amounts of electrical wiring are present, such as factories or data centers. Additionally, solid-bottom trays offer increased security for sensitive cables, preventing potential damage from debris or mechanical wear. Understanding the specific industrial applications of each tray type can ensure that you optimize safety and functionality in your wiring systems.

How to Select the Best Wire Mesh Cable Tray for Your Industrial Needs

| Type of Wire Mesh Cable Tray | Material | Load Capacity | Industrial Application | Dimensions (L x W x H) |

|---|---|---|---|---|

| Standard Wire Mesh Cable Tray | Steel | 200 lbs | Electrical and Data Cables | 2 ft x 12 in x 4 in |

| Heavy-Duty Wire Mesh Cable Tray | Galvanized Steel | 500 lbs | Industrial Plants | 6 ft x 18 in x 6 in |

| Cable Tray with Cover | Aluminum | 300 lbs | Telecommunications | 4 ft x 12 in x 4 in |

| Modified Wire Mesh Tray | Stainless Steel | 250 lbs | Food Processing | 5 ft x 6 in x 3 in |

| Underfloor Wire Mesh Tray | Plastic Coated Steel | 400 lbs | Data Centers | 8 ft x 12 in x 4 in |

Key Considerations for Choosing the Right Wire Mesh Cable Tray Material

When selecting the ideal wire mesh cable tray for your industrial needs, the choice of material is a crucial consideration that can significantly impact performance and longevity. Wire mesh cable trays are typically made from materials such as steel, stainless steel, and aluminum. Steel trays are robust and cost-effective, making them suitable for dry environments where they won't be prone to corrosion. However, they may require additional coatings or treatments in corrosive settings.

Stainless steel offers superior resistance to rust and corrosion, making it an excellent choice for industries exposed to moisture, chemicals, or extreme temperatures. While this material can be more expensive, its durability often justifies the investment, especially in demanding environments. On the other hand, aluminum mesh trays are lightweight and resistant to corrosion, making them ideal for applications where weight is a critical factor. Each material has its advantages, and the right choice depends on your specific environmental conditions and load requirements. Consider not just the initial cost but also the long-term performance and maintenance needs to ensure a wise investment in your infrastructure.

Comparative Analysis of Load-Bearing Capacities in Wire Mesh Cable Trays

When selecting a wire mesh cable tray for industrial applications, understanding the load-bearing capacities is crucial. Different materials and designs can significantly impact the performance and suitability of a tray for specific environments. A comparative analysis reveals that heavy-duty wire mesh trays generally offer superior load capacity compared to lighter options, making them ideal for environments with high cable densities or heavy equipment.

Tip: Consider the installation environment. Humidity, temperature, and exposure to chemicals can affect the durability of the cable tray. Opt for galvanization or powder-coated finishes to improve corrosion resistance and longevity.

Another important factor is the spacing of support brackets, which can influence the overall load capacity. Trays that maintain closer support intervals tend to manage loads more effectively and minimize the risk of sagging. Always refer to manufacturer specifications and load tables to ensure compliance with safety standards.

Tip: Regularly review load requirements and tray conditions during maintenance checks. This proactive approach helps to identify potential overload situations before they become critical, ensuring operational efficiency and safety in your industrial setting.

Load-Bearing Capacities of Different Wire Mesh Cable Trays

Industry Standards and Compliance for Wire Mesh Cable Tray Selection

When selecting a wire mesh cable tray for industrial applications, understanding industry standards and compliance is crucial. According to the National Electrical Manufacturers Association (NEMA), wire mesh cable trays must adhere to specific load-bearing capacities and fire safety regulations outlined in NEMA VE 2-2019. These standards ensure that the trays provide adequate support and maintain integrity in varying environmental conditions, such as extreme temperatures and exposure to chemicals.

Tip: Always verify the product's compliance with recognized standards such as NEMA or Underwriters Laboratories (UL) before purchasing. This ensures that the wire mesh cable trays are tested for durability and safety, which is essential for preventing equipment failure or hazards in your facility.

When assessing your options, consider the material of the wire mesh tray, which should meet industry specifications like ASTM A369 for carbon steel or ASTM B117 for corrosion resistance. Data from the Global Market Insights report indicates that the demand for durable materials has surged by 25% in recent years, reflecting a growing focus on safety and longevity in industrial infrastructure. Selecting the right materials not only complies with regulations but also contributes to the overall efficiency of your cable management system.

Tip: Evaluate environmental conditions and consult with manufacturers about custom solutions that fulfill both your operational requirements and compliance needs. This proactive approach can help mitigate future operational risks related to cable management systems.

Cost-Benefit Analysis: Investing in High-Quality Wire Mesh Cable Trays

When selecting wire mesh cable trays for industrial applications, it's essential to consider not only their functionality but also the long-term cost benefits of investing in high-quality products. According to a report by Research and Markets, the global cable management market is expected to grow by nearly 11% annually through 2027, indicating a significant shift towards more durable and efficient solutions. High-quality wire mesh cable trays, while initially more expensive, can reduce maintenance costs and extend service life, leading to overall savings.

Investing in premium wire mesh cable trays can mitigate risks associated with cable damage and overheating, which are prevalent in industries that require extensive electrical wiring. A study by the National Electrical Manufacturers Association highlights that proper cable management reduces installation costs by up to 30% and minimizes downtime caused by electrical failures. This evidence supports the notion that high-quality trays are not just a purchase but a strategic investment that pays off through enhanced operational efficiency and reduced risk of costly repairs.